As medical devices continue to shrink in size whilst increasing in complexity, engineers are under growing pressure to deliver reliable mechanical performance within ever-tightening spatial constraints. Springs remain a fundamental part of many medical mechanisms, but traditional coil springs can limit how compact a design can be.

Wave springs offer a compelling alternative. By delivering equivalent force in a significantly reduced installation height, they enable designers to rethink internal architectures without compromising performance. They may not be suitable for every application, but certain medical devices are particularly well matched to the unique characteristics of wave springs.

Devices driven by miniaturisation

Miniaturisation is one of the strongest drivers of wave spring adoption in medical design. Devices that need to be portable, handheld or wearable often face strict limits on internal space, making spring cavity height a critical constraint.

Wave springs are especially well suited to:

- Compact drug delivery devices

- Handheld diagnostic equipment

- Devices with high assembly and repeatability requirements

In these applications, reducing axial height by even a few millimetres can unlock a significant amount of design freedom. Wave springs can provide the required compression force in roughly half the height of a comparable coil spring, allowing designers to either reduce overall device size or reallocate space to other functional components.

The case for drug delivery devices

Drug delivery systems are among the most promising use cases for wave springs. Devices such as insulin pens, autoinjectors and inhalers rely heavily on precise, repeatable mechanical forces to ensure accurate dosing and reliable operation. Wave springs are well suited to these devices because they offer:

- Predictable, consistent axial loads

- Compact geometry for tight internal assemblies

- Tangle-free handling during automated assembly

In pen injectors and autoinjectors (where internal space is limited and force consistency is critical) wave springs can support smoother actuation and tighter control over delivery mechanisms. Their reduced height can also help manufacturers design slimmer, more ergonomic devices that are easier for patients to use and carry.

Handheld diagnostic and surgical instruments

Many handheld medical instruments rely on springs for tactile feedback, actuation or controlled movement. Examples include diagnostic tools, sampling devices and certain minimally invasive surgical instruments.

Wave springs can be advantageous in these applications where:

- Internal layouts are dense and space is at a premium

- Consistent force feedback is required

- Assembly efficiency and repeatability are important

By reducing spring height, wave springs can simplify internal layouts and support more compact instrument designs. Their predictable load characteristics also help ensure consistent feel and function across high production volumes.

Devices with high assembly and repeatability requirements

Beyond specific device categories, wave springs are particularly suited to medical products that demand high manufacturing repeatability and efficient assembly processes.

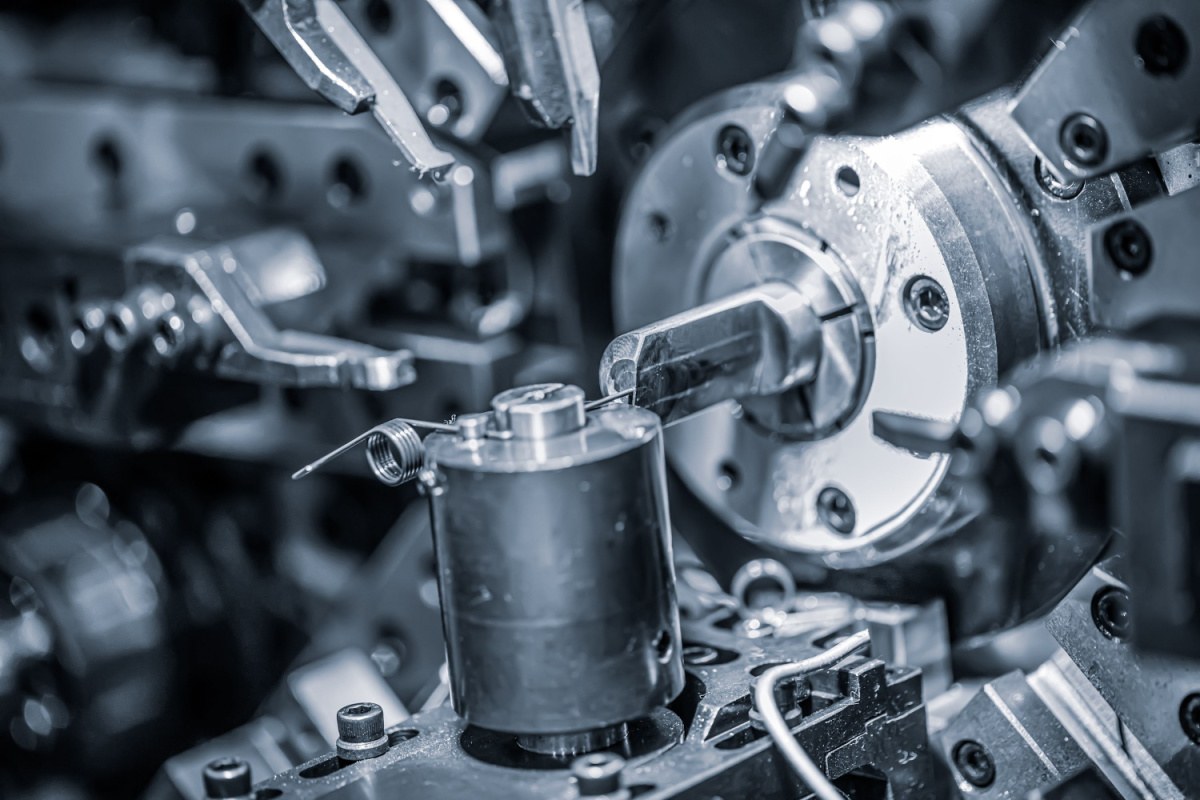

Traditional coil springs can tangle, deform or vary during handling, especially in small or fine geometries. Wave springs, by contrast, are inherently resistant to tangling and are easier to handle in automated assembly environments. This can reduce assembly disruptions and minimise component damage, which can be just as important as performance benefits for medical devices produced at scale.

When wave springs may not be suitable

While wave springs offer clear advantages, they are not a universal replacement for coil springs. They are designed specifically for axial compression and are not suitable for extension or torsional applications. On top of this, they cannot always be dropped into an existing coil spring cavity without redesign. As a result, wave springs are best considered early in the design process, where cavity dimensions, tolerances and load requirements can be optimised around their geometry.

Designing with wave springs in mind

Wave springs can unlock meaningful improvements in medical device design, particularly in places where miniaturisation, force consistency and assembly efficiency are important. Devices such as drug delivery systems and compact handheld instruments stand to benefit most from their reduced installation height and predictable performance.

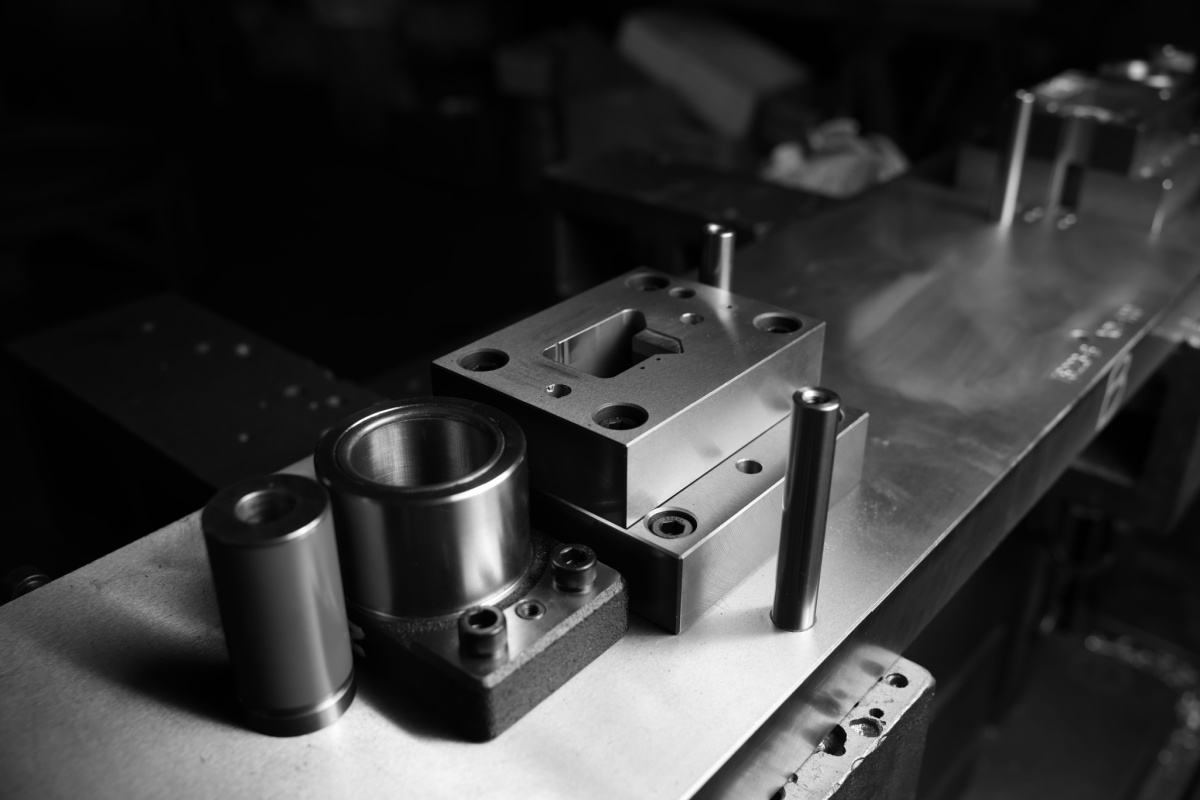

However, achieving these advantages in practice depends on far more than the spring itself. Successful integration requires careful consideration of tolerances, surrounding components, material interactions and high-volume manufacturability from the earliest design stages.

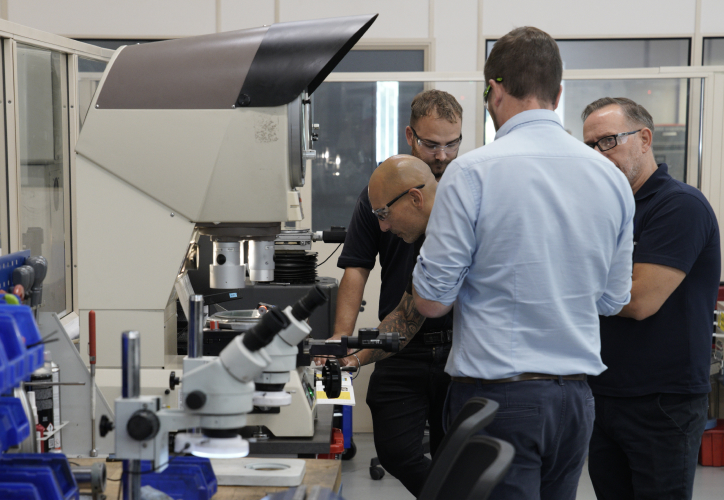

This is where specialist manufacturing expertise from a partner like Advanex Medical becomes invaluable. Advanex Medical works alongside device designers to support robust, compliant mechanical design through deep experience in medical-grade springs, precision metal components and design-for-manufacture principles. By helping engineers optimise component interfaces, manage tight tolerances and design for repeatable, scalable production, Advanex Medical reduces risk and accelerates the path to approval and volume manufacture.

If your next device demands compact, dependable mechanical performance, download our guide below to discover how Design for Pharmaceutical manufacturing practises act as a foundation of proven expertise and trusted component quality.

.jpg?width=352&name=shutterstock_1051333151%20(1).jpg)