ISO 13485, the international standard for quality management systems (QMS) in medical device production, plays a critical role in ensuring safety, repeatability and regulatory approval. As regulatory scrutiny continues to intensify across the globe, forward-thinking manufacturers are adopting a compliance-by-design mindset. This is by embedding ISO 13485 principles right into the component design, manufacturing processes and documentation trail from day one.

To fully integrate this mindset, engineers need an understanding of what ISO-13485 compliance-by-design means and why integrating it early in the product lifecycle is essential for medical device OEMs working with pre-manufactured components.

What is ISO-13485?

ISO 13485:2016 is an internationally recognised standard developed specifically for medical device manufacturers and their supply chains. It outlines the requirements for a comprehensive quality management system that demonstrates an organisation’s ability to consistently meet customer and regulatory requirements for medical devices and related services.

It is based on the structure of ISO 9001 but with additional requirements that focus heavily on:

-

Risk management throughout product development and manufacturing

-

Detailed documentation and traceability

-

Validation of processes (especially where the final output cannot be fully verified by inspection)

-

Effective management of sterile environments and cleanliness

-

Design controls, corrective actions and complaint handling

Importantly, ISO-13485 is often considered the benchmark for gaining CE marking in the EU and is also required or recognised in many other jurisdictions, including the US, Canada, Japan, Australia and Brazil. Certification is typically a prerequisite for selling devices internationally.

Compliance-by-design - moving from cost to competitive advantage

Where compliance can often be seen as a burden (costly, time-consuming and restrictive), a compliance-by-design approach flips the narrative. It treats regulatory alignment as a value-adding design principle and one that simplifies audit readiness, reduces non-conformance risk and accelerates market entry.

This is particularly relevant for medical device OEMs who rely on pre-manufactured components like springs, wire forms and ultra-thin pressings. If a component is not manufactured to ISO 13485 standards, any defect or traceability gap can cascade through the value chain, potentially invalidating the entire device during validation or inspection phases.

By contrast, when ISO 13485 requirements are baked into the early design and production stages, it ensures:

-

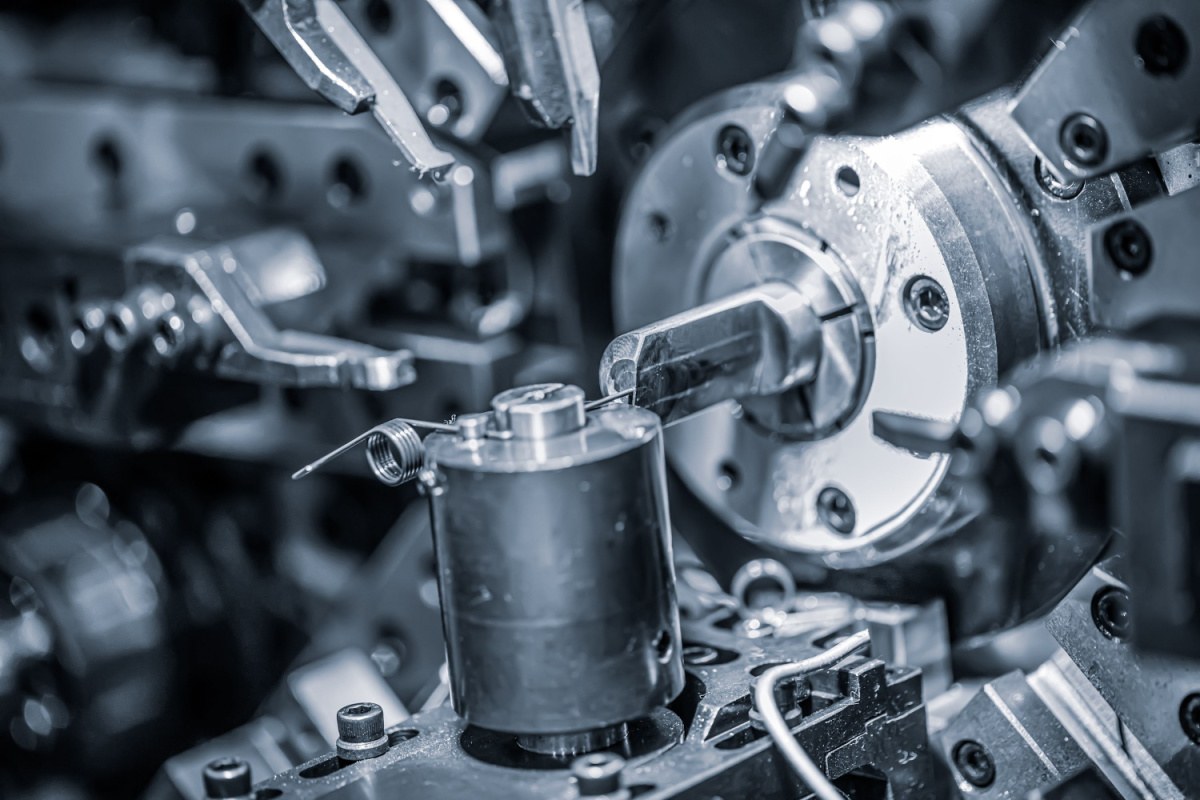

Repeatability across batches and geographies: Certified processes reduce variation and ensure global consistency across suppliers.

-

Cleanliness and particulate control: Cleanroom-level production environments and surface finishing reduce the risk of contamination, which is particularly critical in inhalers and implantable devices.

-

Traceability and documentation: Lot codes, inspection reports and digital process validation make it easier to support CAPA investigations, MDR submissions and audits.

-

Streamlined design approvals: With compliance assumptions already embedded in each component’s design, OEMs can avoid delays caused by retrospective process validation or rework.

Key components of ISO-13485 compliance-by-design

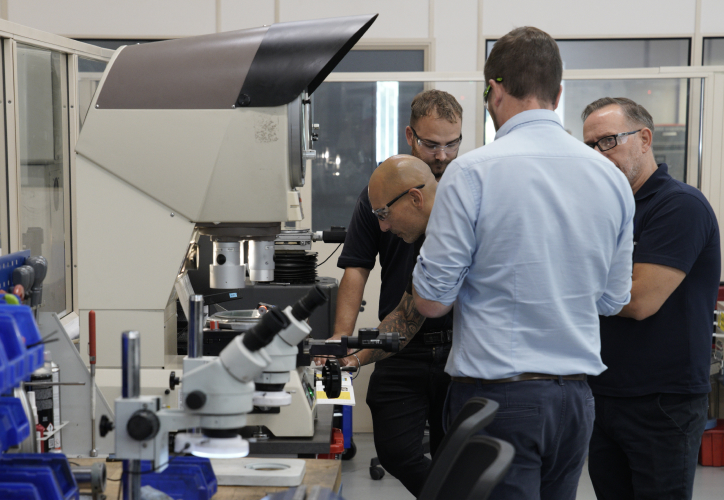

To design compliance in from the start, manufacturers and their partners should pay close attention to the following ISO 13485 elements.

1. Risk-based thinking

Every design decision (from material selection to tolerances) should be evaluated for potential patient risk. ISO 13485 mandates a risk management file for each product, updated throughout the lifecycle.

2. Process validation

Processes that impact quality (e.g. laser deburring, micro-pressing, or automated inspection) must be validated, especially if final output cannot be inspected without damaging the product.

3. Document control

ISO 13485 requires strict control over documentation, including design history files (DHF), device master records (DMR) and production records. Component manufacturers must maintain and provide this documentation to downstream OEMs.

4. Design and development planning

Design controls must be embedded into the project from the outset. This includes design reviews, verification and validation procedures, and the ability to demonstrate how each requirement is met.

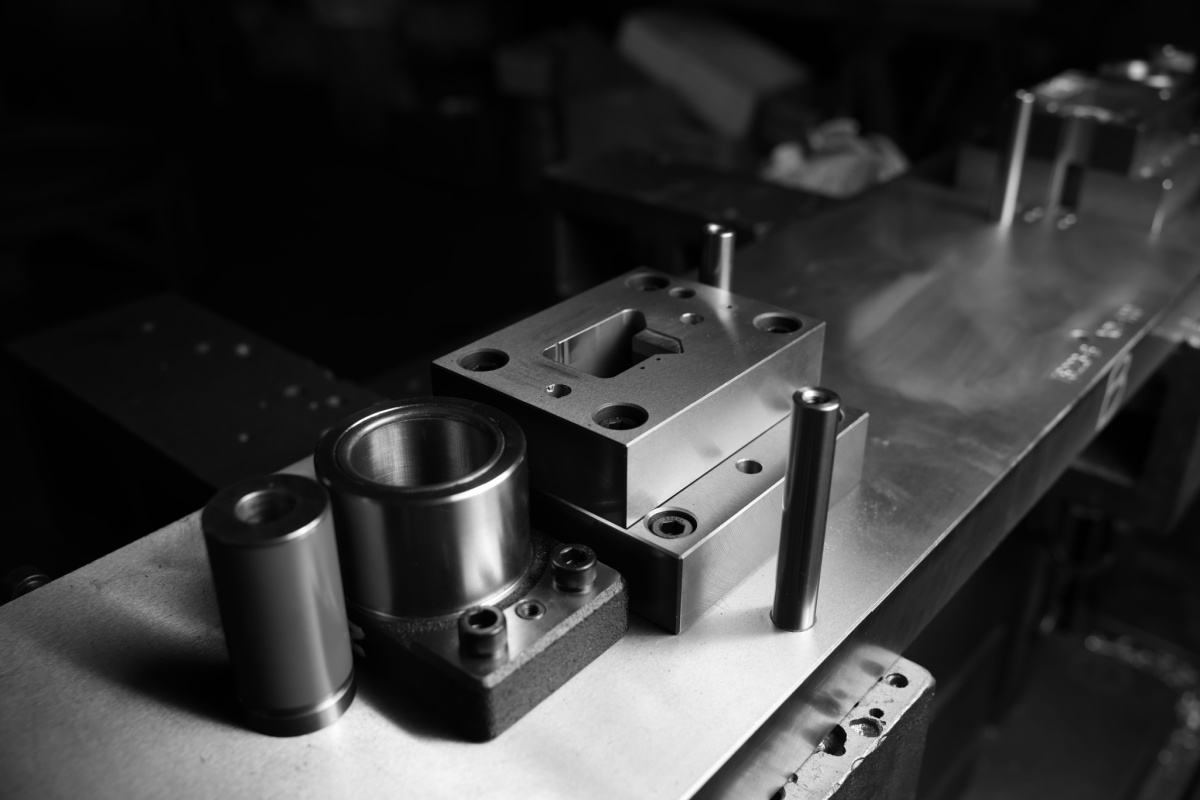

5. Clean manufacturing environments

ISO 13485 underscores the importance of cleanliness and bioburden control, especially for components that are used in sterile or patient-contacting applications. Surface roughness, debris and particulates are seen as non-compliances during validation.

Why OEMs need to pay attention even at the component level

Many medical device OEMs mistakenly treat ISO-13485 certification as something to worry about at the final assembly or packaging stage. But in practice, compliance at the component level is equally important. Even minor issues like a poorly documented surface finish, or out-of-spec dimensions can result in costly delay, or even failed regulatory submissions.

With increasing regulatory convergence, particularly through frameworks such as the EU MDR and FDA’s Quality System Regulation (QSR), the component supply chain is now squarely in the spotlight. Working with ISO 13485-certified partners can help ensure that OEMs benefit from validated processes, documented controls and clean production from the outset helping them stay compliant and competitive across global markets.

Start with compliance to scale with confidence

ISO-13485 compliance-by-design is a smart, scalable way to de-risk device development and streamline regulatory approvals. For OEMs working with critical pre-manufactured components, embedding ISO standards at the earliest design stages reduces rejection rates, improves traceability and speeds up time to market.

Advanex Medical’s investment in ISO-certified, traceable and cleanroom-level manufacturing ensures every component is audit-ready from the moment it leaves the production line. That’s what compliance-by-design means in practice: cleaner processes, fewer surprises and a smoother path to global approvals.

.jpg?width=352&name=shutterstock_1268589469%20(1).jpg)