Entanglement is the result of spring coils becoming interlocked and compromising a spring’s ability to actuate. This is a prominent design challenge as it inhibits devices from performing their desired function, putting patients at risk. These springs also become irreparable, resulting in wasted components and limited manufacturing volume.

You need to integrate processes that minimise this risk of entanglement in both manufacturing and packaging, with the latter being a common place entanglement takes place. These need to be implemented from the outset of your design to maximise manufacturing efficiency and reduce scrap rates.

In this article, we explore these factors and highlight the methods of prevention to avoid the risk of entanglement.

Design flaws

One of the most common causes of spring entanglement is inconsistency and flaws with the overall device design. This is a direct result of the miniaturisation of pharmaceutical devices to bring ease-of-use for patients and specific application benefits for medical professionals. A consequence of this miniaturisation is limited internal space for springs to actuate, increasing the risk of entanglement.

- Spring index - Spring index describes the relationship between spring wire diameter and outside diameter. A larger index translates to a smaller wire diameter for compact designs. However, an index that exceeds values of 10 leads to heightened risk of spring entanglement.

- Clearance space - Limited clearance space for pharmaceutical springs can easily result in spring entanglement. It can lead to interference between multiple springs or with the internal casing of the device, increasing the chance of entanglement during actuation.

- Improper spring alignment - The improper alignment of springs within pharmaceutical designs directly leads to entanglement from becoming twisted or intertwined. This highlights the need for designs to incorporate alignment from the beginning of design to minimise this risk.

Insufficient lubrication

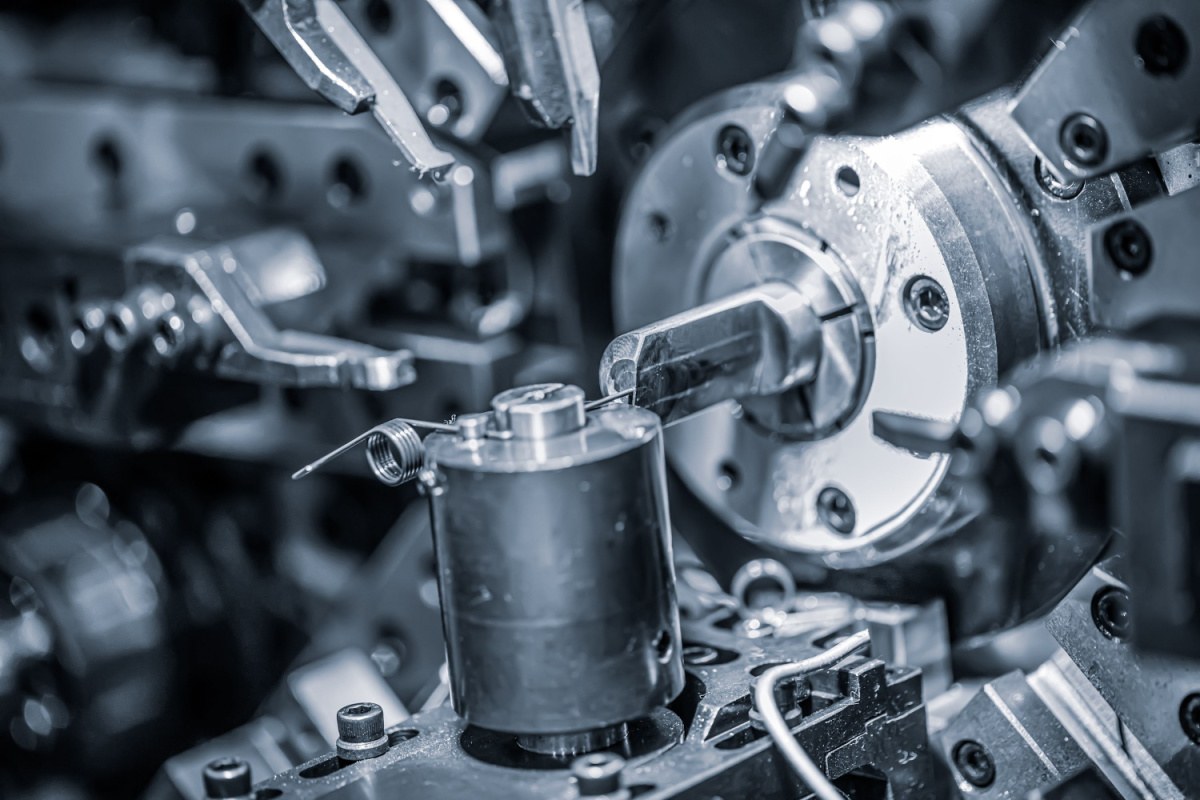

Lubrication is necessary for medical springs for a number of reasons. Firstly, it prolongs their lifespan by reducing the impact of friction-induced wear over multiple actuations. Secondly, it aids in the initial coiling process during spring manufacture. And thirdly, it helps prevent spring entanglement.

Lubrication aids in the prevention of spring entanglement by reducing the friction between coils and other springs during actuation. This helps them move along their intended path of motion without the risk of entanglement. Insufficient or no lubrication directly increases the risk of entanglement, and can often be an inevitability in a number of cases.

Poor manufacturing processes

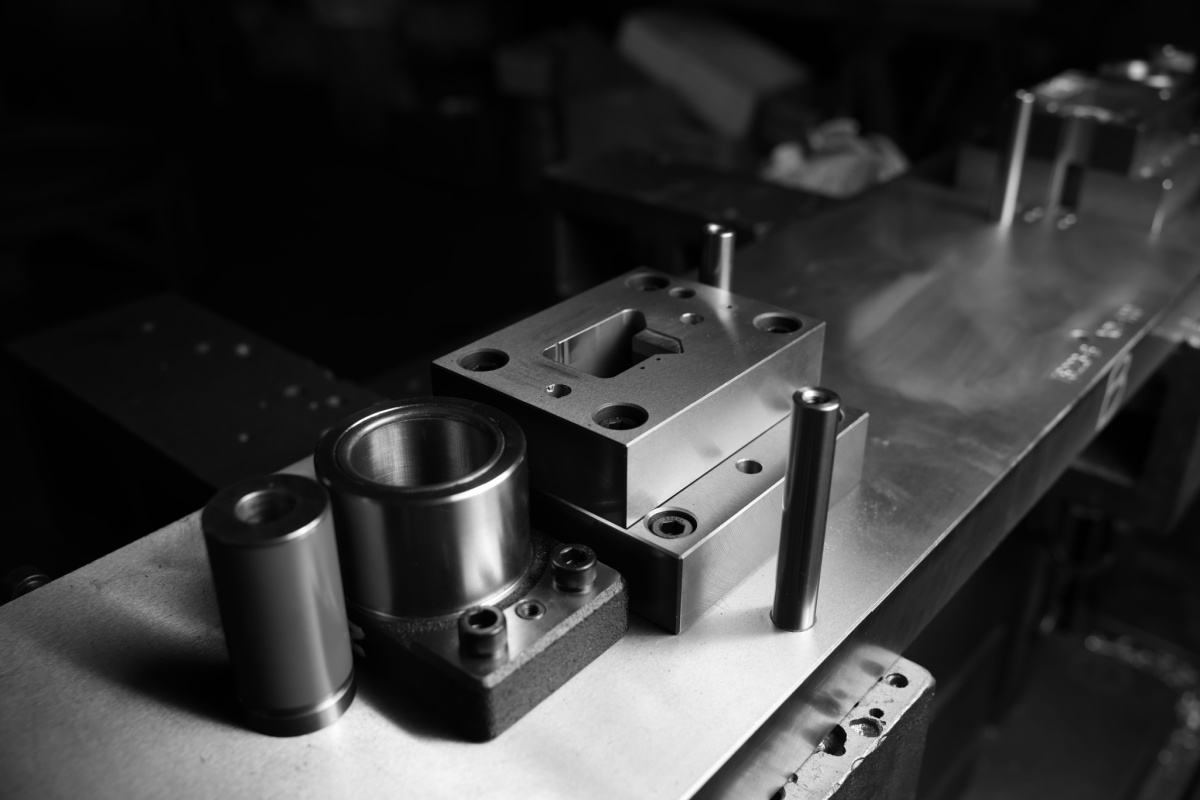

Expert manufacturing paired with expert design is the key to minimising the risk of spring entanglement. Coiling is a key example of this, as traditional spring coilers continuously push wire against an inclined tool to force the wire to bend and form a coil. This generates high levels of friction, requires lubrication and greatly restricts the rate at which the coil can be formed.

A consequence of using traditional coilers are rough edges on the surface of the spring, increasing the likelihood of entanglement when in operation from heightened friction. Without dedicated manufacturing processes like deburring to minimise this surface roughness, spring entanglement can become a common occurrence in devices using these springs. Other steps in manufacturing like cutting can also produce rough edges, highlighting the importance of evaluating every step of your spring’s journey through manufacture.

Preventing spring entanglement by design and manufacture

Each of the factors contributing to spring entanglement share the same preventative measure: taking it into account from the very beginning of the design cycle. Establishing the right spring index, internal device dimensions and required spring clearance are crucial to minimise the risk of entanglement and maximise the performance of your device. Alongside this, there are additional elements of spring design that can help you minimise the risk of entanglement.

- Surface finish and material composition - The material makeup and surface finish of springs can provide additional lubrication for springs as a preventative measure for entanglement. Examples include nickel-based compositions that provide natural lubricity, as well as an oiling coating that adds an additional layer of lubrication.

- Specialised processes - Dedicated manufacturing processes can directly minimise the risk of spring entanglement. One example is wrapping a wire around a rotating mandrel whilst coiling as it generates less friction when compared to traditional methods. Another key example is deburring processes near the end of manufacture to minimise surface friction and smooth out rough edges. There are a number of ways you can eliminate the risk of entanglement through specialised manufacturing processes.

- Additional design elements - Through considering spring entanglement at the initial stages of the design cycle, you can integrate dedicated preventative elements to minimise the risk of entanglement. This can include spring spigots that prevent twisting or internal separators that prevent individual springs from coming into contact. The key is to have entanglement in mind from the beginning of design rather than at the end.

Have a trusted design and manufacturing partner to minimise the risk of spring entanglement with Advanex Medical

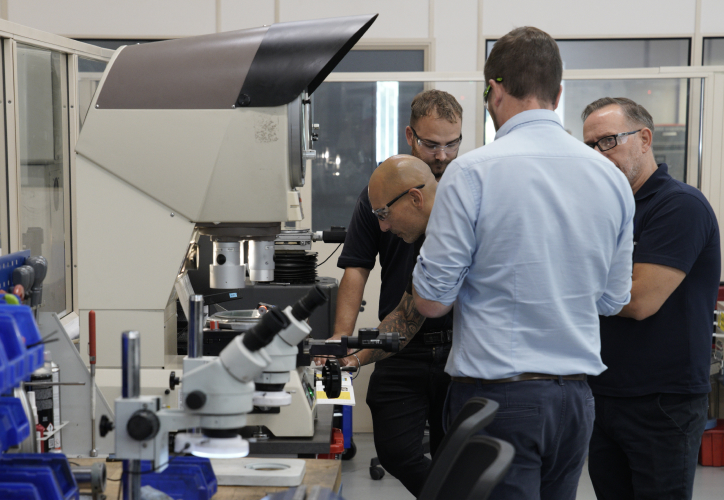

Pharmaceutical devices are complex and require close attention to make sure each component is performing how it’s supposed to. Springs are a key aspect of this, and the challenge of entanglement is a big hurdle that can stop many designs in its tracks. As a solution, you need a design and manufacturing partner that has expertise and experience in minimising the risk of entanglement.

Advanex Medical is your on-call partner for everything from springs, deep drawing, wire forming, and more, to help you design, manufacture, and develop market-defining drug delivery devices. With globally located, medical-grade facilities and in-house medical expertise, we’re here to provide you with the support and expertise you need through every stage of your product’s lifecycle.

To see how we can support you in developing a high-quality, easy-to-assemble medical device that goes to market seamlessly, get in touch with one of our experts.

.jpg?width=352&name=shutterstock_1051333151%20(1).jpg)