Springs in medical devices need to support the design and function of their device through reliable compression/extension over extended use/periods. They also need to be resistant to wear and relaxation to be compliant with stringent regional and international regulations.

Simplifying the integration of springs can make reaching these above requirements easier. This can be achieved through specific material compositions, surface finishes and specialised manufacturing processes that suit the needs of your device and your project.

In this article, we go over the critical factors that go with medical spring integration, and the steps in spring manufacture to help with device assembly.

Aspects of medical spring integration that ensure performance

Appreciate application and device’s environment of operation

The performance of your medical device is defined by its application and environment. Specific designs require different spring features, such as corrosion or relaxation resistance. Because of this, you need to have a clear understanding of the operating conditions and requirements of the device.

For example, a single use device will have little need for high spring actuations when compared to an inhaler. Instead, it will have greater demands of resistance to corrosion and spring relaxation so that the device can perform its function when it is eventually needed. Understanding the application and operating environment is required to ensure correct and effective spring integration.

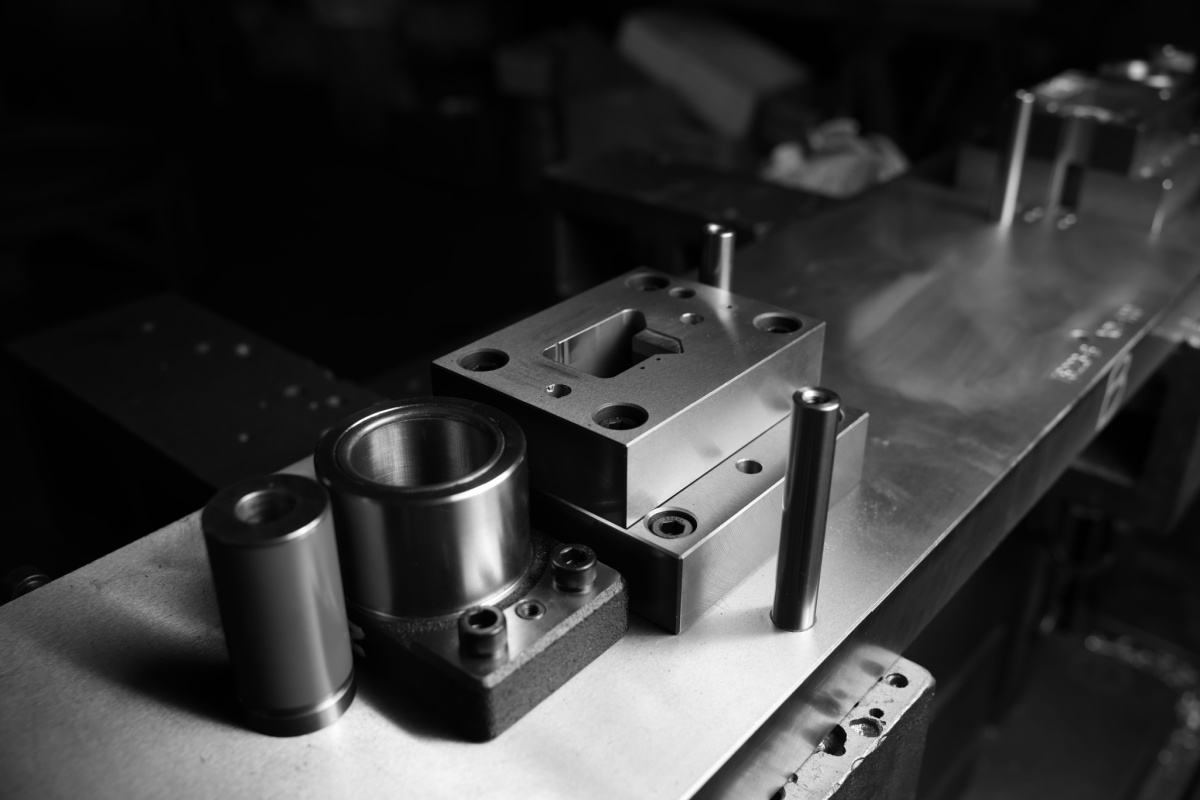

Internal and external dimensions of the design

Size of the medical device is a crucial element in medical spring integration. Lightweight and compact form factors are more common than ever as they enhance portability and make it easier for patients to carry their medication. However, smaller designs pose a greater challenge for spring integration.

Springs have an index which is the relationship between wire and outside diameter. The smaller the spring size and index, the harder it is to coil the spring. On the other hand, a spring is prone to entanglement with a higher index which inhibits functionality. Too high or too low an index can also impact spring lifespan, lead to fatigue and result in poor performance. Because of this, understanding the size limitations of the design is crucial to establishing the right spring index.

.png?width=512&height=357&name=unnamed%20(13).png)

Particulate contamination

Regardless of the specific application, medical devices face a range of stringent regional and international regulatory requirements. This is to both protect patients from possible device faults and ensure they receive the healthcare expected of it; any deviation from this expectation can lead to situations such as an overdose or underdose, which can have detrimental health implications.

Medical springs are a pillar of medical device functionality, and fall under these stringent regulations as a result. They need to meet cleanliness guidelines to minimise the risk of particulate contamination that can lead to health complications. Understanding these specific compliance requirements is essential to spring integration.

Surface coating

Alongside material composition, surface coating technology provides additional protective features to enhance the performance and integration of medical springs. For example, nickel coated springs provide a layer of lubricity that helps the spring perform and conforms with cleanliness regulations. In comparison, some lubricants can introduce particulates and fail compliance as a result. This helps ensure the medical device passes through clinical trials and eases spring integration.

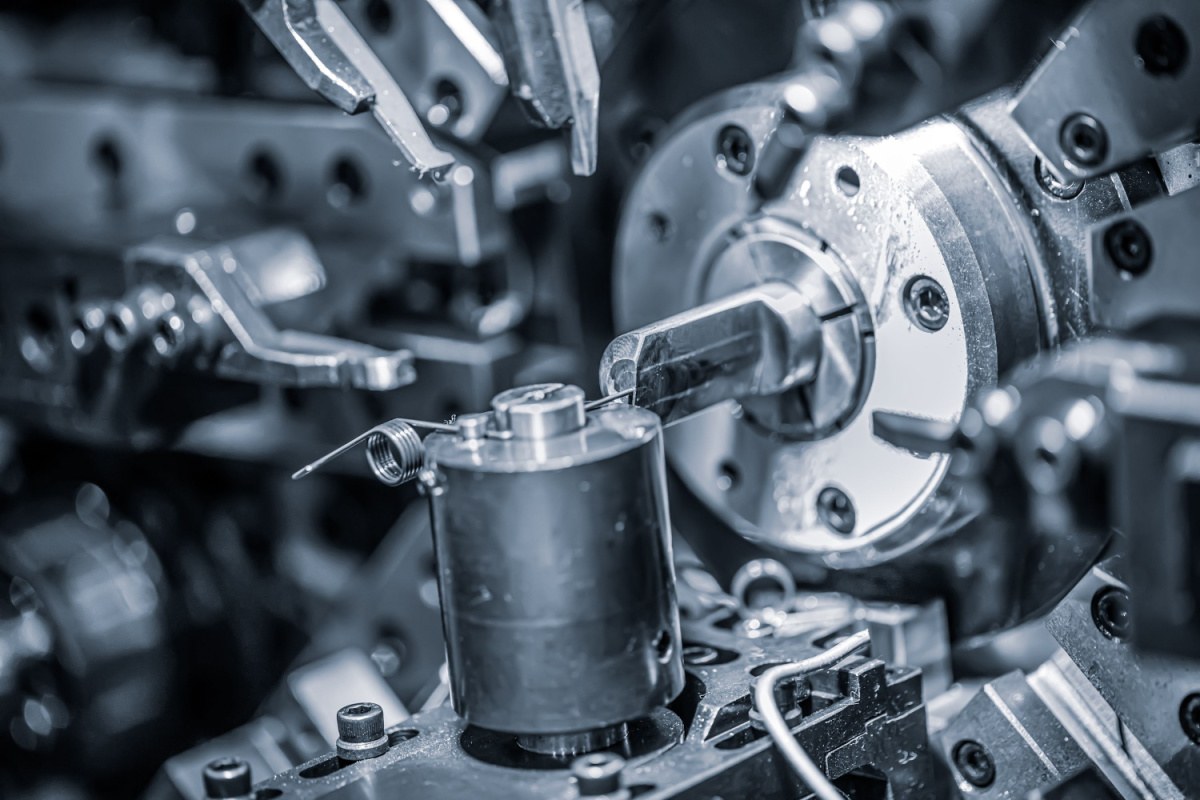

Specialised manufacturing

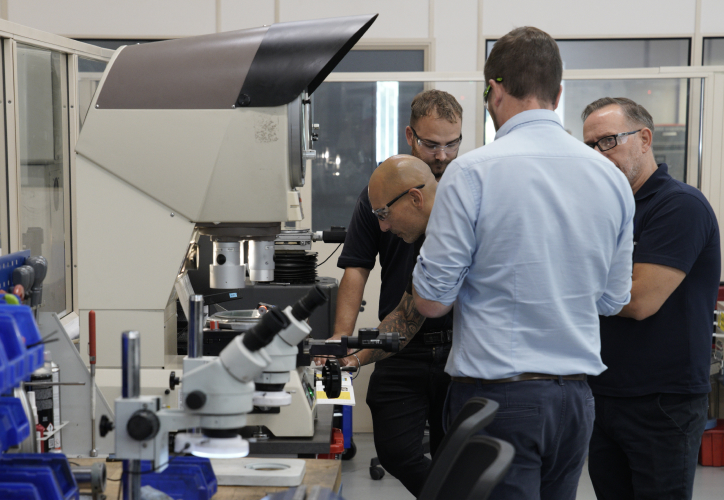

Specialised manufacturing processes and systems can enhance medical spring integration through precision. These include computer simulation technology, specialised calculation programs and structure analysis processes. By using these technologies, you can determine the perfect spring index to get the best performance of a spring within a certain area. As a result, you can integrate springs into small form factors and maintain good performance and ensure compliance.

Advanex Medical - Performance, compliance and resilience guaranteed to make spring integration simple

Medical springs are a vital component of medical devices. Because of this, careful consideration needs to be taken during integration for performance, reliability and compliance to be assured in your final product.

At Advanex Medical, we provide a range of spring types and compositions to help you integrate the perfect solution for your design. Our material compositions include steels, copper and nickel alloys, Titanium, Elgilloy, Hastelloy, Kanthal and others.

We have a number of finishing and post-cleaning options available in-house, ranging from electroplating, organic zinc coatings and much more. We also have a talented team of product design specialists to help you with your spring integration needs.

To find out more about our products or to get additional pricing information, contact a member of our team today.