In pharmaceuticals manufacturing, the quality of final products is not only a matter of pride, but one of health and safety concern. With many products using metallic, precision components, one of the most overlooked issues is related to particulates and contaminants.

Particulate matter is a natural byproduct of the transformation process for many types of components. In many industries, high levels of particulate matter are inconsequential. However, in the pharmaceutical industry, many devices will fail validation and verification if there is any presence of particulates.

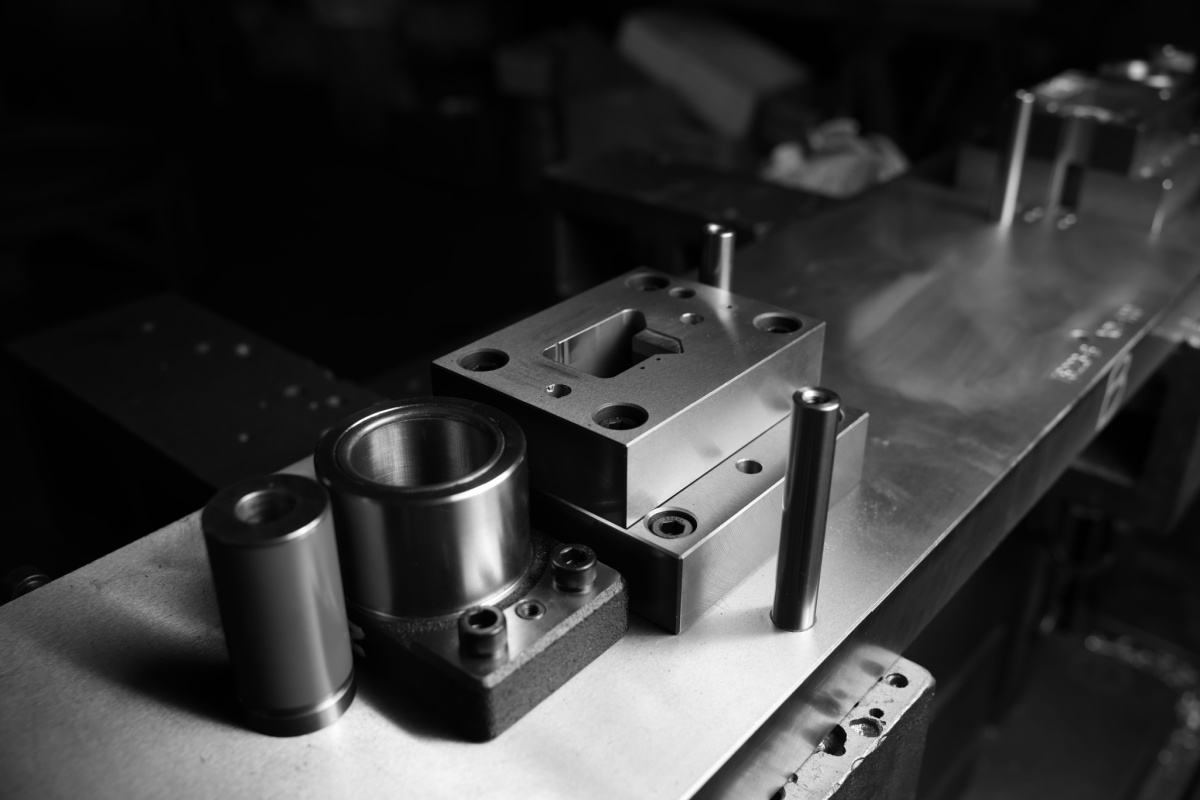

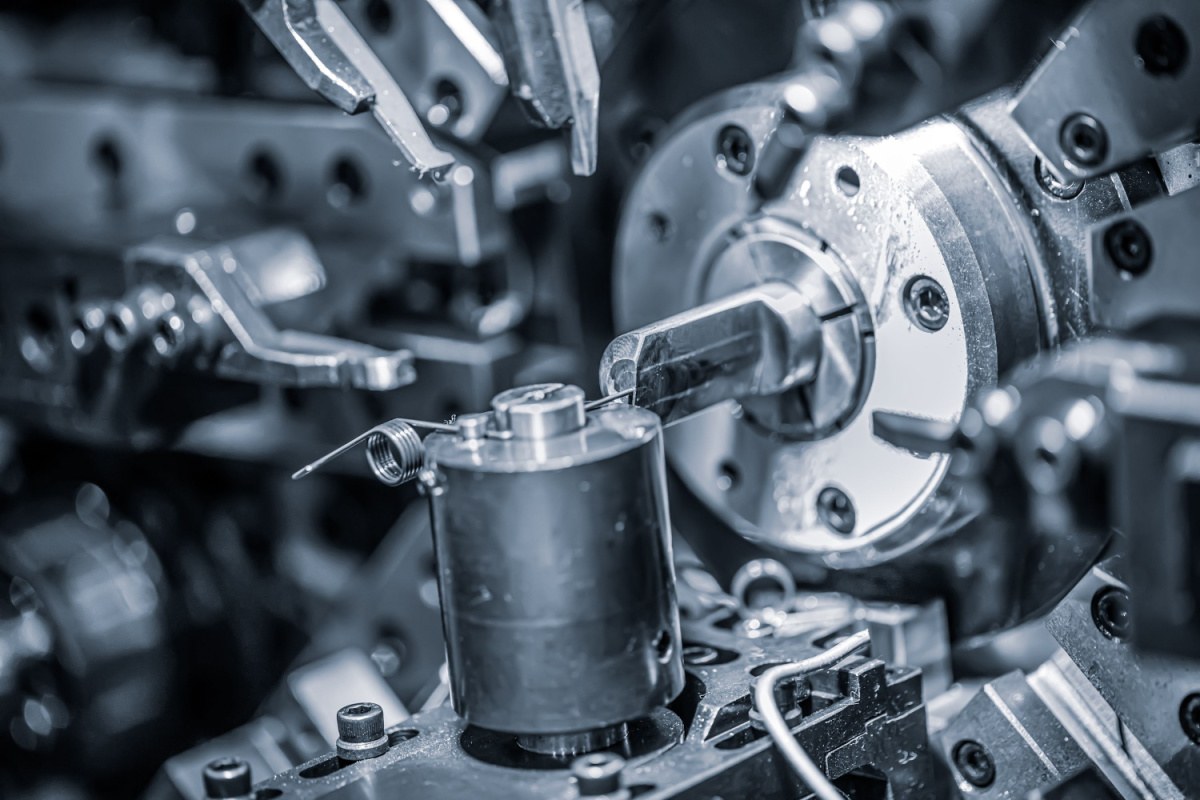

The chosen route to resolve particulate issues is through deburring. Traditional deburring methods are often the solution to prevent the creation of particulates. However, with thin wire forms, they can produce deformations. For example, using synthetic media or manual sieving will distort thin wire often found in miniaturised medical devices.

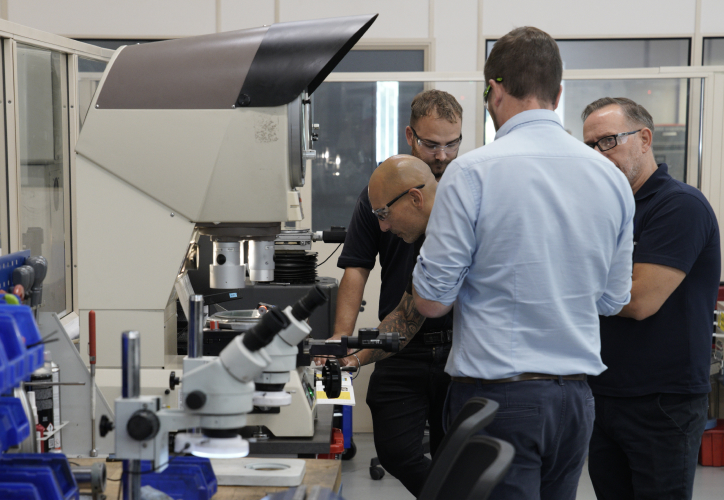

In this case study, we explain how we introduced an innovative in-line laster deburring process into an automated production line for a specialised functional wire form. Working with the pharmaceutical company and a third-party moulder, Advanex Medical helped diagnose an issue that only arose during mass production. Within a matter of days, Advanex Medical developed a novel solution that enabled the world's largest pharmaceutical company to successfully go to market with their strongest commercial offering in many decades.