The integration of miniature mechanical components has become a cornerstone of medical device innovation. Among these components, medical springs play a pivotal role in enabling compact, precise, and repeatable drug delivery mechanisms from dry powder inhalers to auto-injectors and dose counters.

Designing these devices for reliability and durability from the outset is crucial to achieve regulatory approval. To achieve this, engineers must expertly balance material selection, tolerance control and validation testing. Additionally, they need an understanding of how these three pillars ensure medical springs perform consistently in compact drug delivery devices, helping manufacturers meet stringent regulatory and functional demands.

The challenge with spring miniaturisation

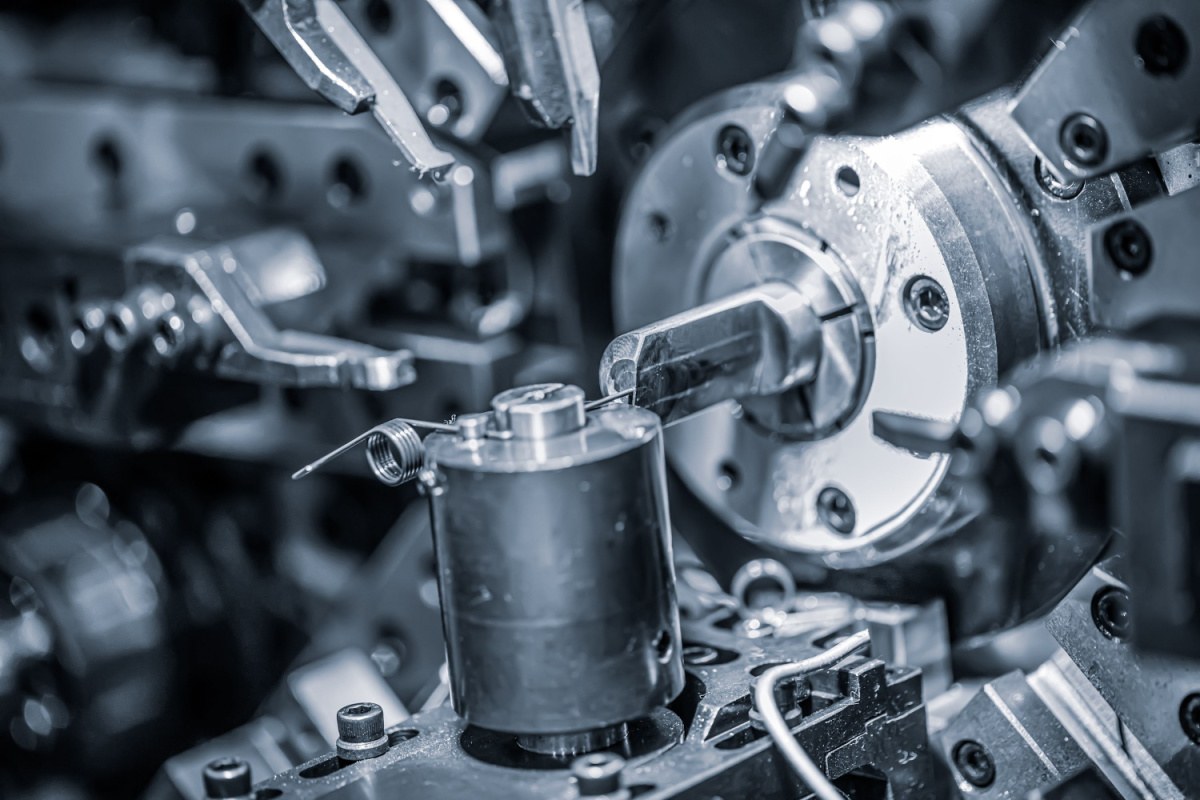

Springs are at the heart of the actuation mechanisms within drug delivery systems. Whether providing the kinetic energy to deploy a needle, count doses or eject a drug cartridge, springs need to perform their function thousands (or millions) of times without failure.

When it comes to the miniaturisation of these components through micro-springs, further complexity arises. They need advanced engineering to prevent deformation, fatigue or misfiring which can be a challenge in space-constrained environments. This is vital as a failure in a spring mechanism can directly compromise drug efficacy, patient safety and product approval.

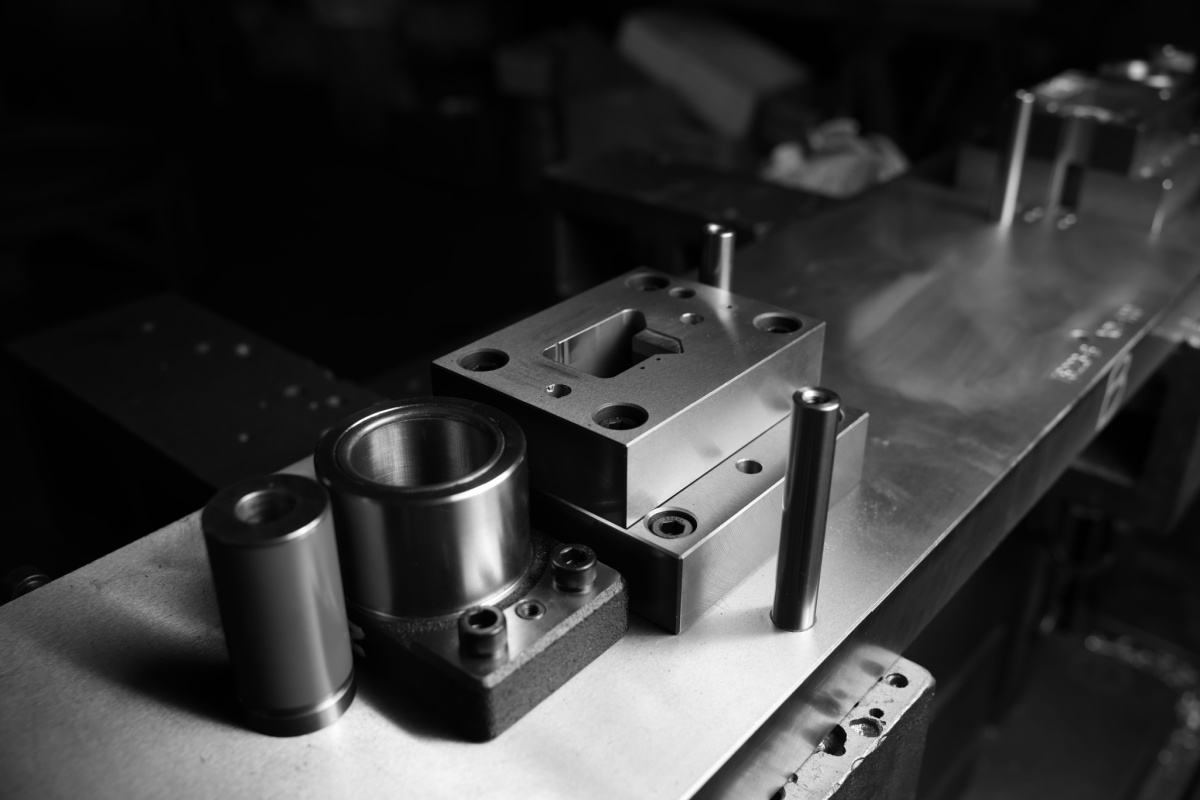

Tolerance control - precision that drives reliability

Drug delivery devices operate under extremely tight engineering constraints. Springs used in these devices must meet micrometre-level tolerances to ensure consistent performance across millions of units. Even minor deviations can alter actuation force or timing, leading to failures in dose delivery or compliance. When springs are tightly toleranced from the outset, they improve device function and reduce rejection rates/manufacturing costs by increasing yield. To achieve this, there are various methods that can be used.

- Micropressing technology: Used for ultra-thin components with critical spring geometries.

- Advanced forming and measuring systems: These ensure each spring meets design specifications with minimal variation, supporting batch-to-batch repeatability.

- Simulation and FEA modelling: Finite element analysis is often used in the design stage to optimise stress distribution and deformation characteristics.

Material selection and why nitinol and other alloys are important

Choosing the right material is foundational to a spring's performance. For springs in drug delivery devices, materials must offer superior fatigue resistance, corrosion protection and the ability to maintain mechanical properties at micro scales. Nitinol, an alloy of nickel and titanium, is often a preferred choice thanks to its unique features.

- Elasticity: It can undergo substantial deformation and return to its original shape, making it ideal for devices that require repetitive, precise movement.

- Biocompatibility and corrosion resistance: Crucial for components that may come into contact with drug formulations or bodily fluids.

- High fatigue life: Enables long-term use without mechanical failure, especially in reusable inhalers and injectors.

In addition to Nitinol, phosphor bronze and nitronic stainless steels are also used in wire forms for their balance of strength, formability and corrosion resistance.

Validation testing to ensure performance across every unit

Even with the best design and materials, real-world performance must be validated. Comprehensive testing and inspection protocols are required to ensure that every spring meets functional expectations before integration into the final device. Validation approaches include load and fatigue testing for performance across repeated cycles, environmental testing for performance in specific conditions and particulate and contaminate control to ensure regulatory approval through processes like laser deburring.

The key to success through integration at the design stage

Springs should not be an afterthought. Integrating them into the design from the outset (rather than retrofitting around them) can reduce development timelines, improve manufacturability and ensure compliance.

This Design for Pharmaceutical Manufacture (DfPM) approach includes selecting compatible spring materials early in the design cycle, ensuring spring geometries fit within tight spatial constraints and partnering with specialists who can provide form-to-function analysis and prototyping feedback. By aligning engineering decisions with manufacturing realities, design teams can streamline approval and accelerate time-to-market.

Partnering for long-term precision

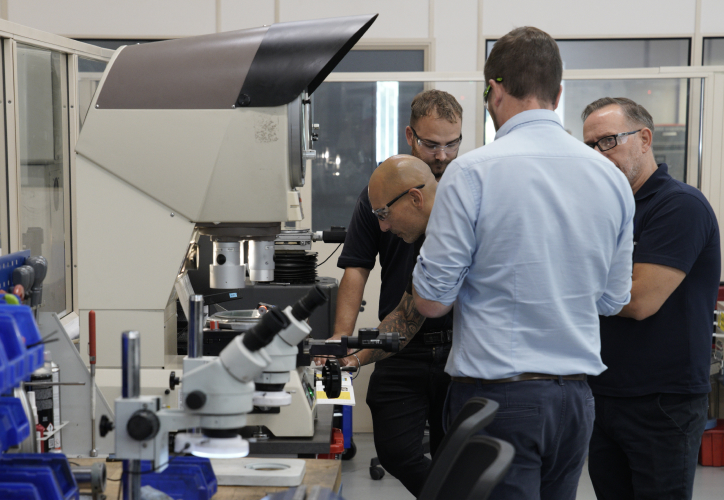

Bringing a compact, reliable drug delivery device to market is no easy feat. With tight tolerances, challenging materials and unforgiving validation standards, it pays to partner with a manufacturer who specialises in medical spring integration.

Advanex Medical is at the forefront of this field. With deep expertise in wire forming, micro spring development, and integrated testing, we provide support from initial concept through to full-scale production, helping your drug delivery device meet the highest standards of reliability, durability and performance. To learn more about how Advanex Medical can help you design with confidence, download our guide below.

.png)