Developing a prototype that satisfies design expectations is just the beginning of a medical device’s journey. The real challenge lies in transforming that prototype into an efficient and compliant design that can be reliably manufactured at scale.

To achieve this, designers need a clear understanding of key areas like manufacturing processes, critical tolerances and the technologies to invest in that ensure precision across thousands of production cycles.

Adopt a Design for Pharmaceutical Manufacturing (DfPM) mindset as early as possible

Prototypes focus on function and form, but scaling to mass production requires a deep dive into manufacturability. From the outset, devices must be evaluated for key aspects from ease of assembly to material compatibility. Components with high edge roughness, complex geometries or unsuitable finishes can introduce rejection risks during trials and routine inspections. By designing with manufacturability in mind, engineering teams can reduce the need for post-processing and minimise variables that complicate scale-up.

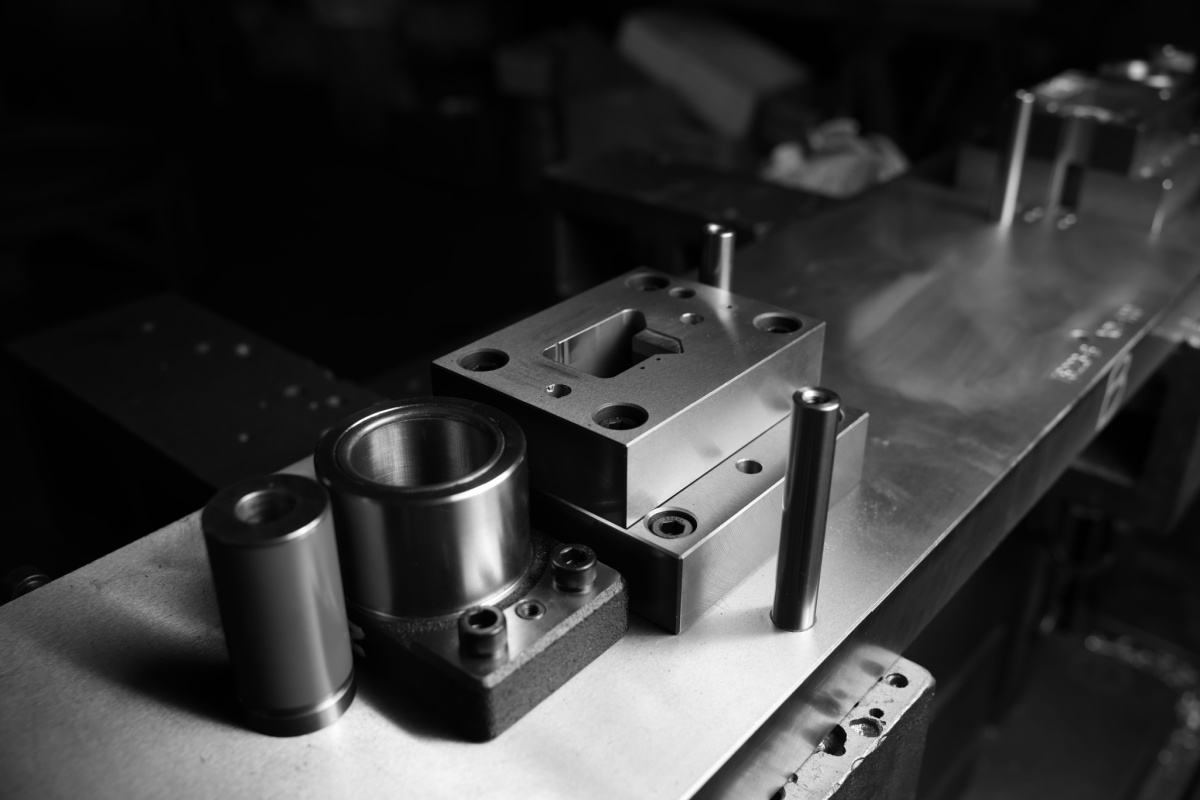

Define tolerances for high-volume precision

One of the most frequent roadblocks in scaling is the mismatch between prototype tolerances and what is achievable in mass production. Tolerances that are too tight increase manufacturing complexity and scrap rates, whereas overly loose tolerances risk functional failure. Either way, both pose complications when it comes to passing medical trials. To avoid this, there are a number of steps you can take to ensure compliance along with cost-effectiveness.

- Use statistical process control to assess achievable tolerances.

- Simulate component stress points using FEA tools to understand how variance impacts performance.

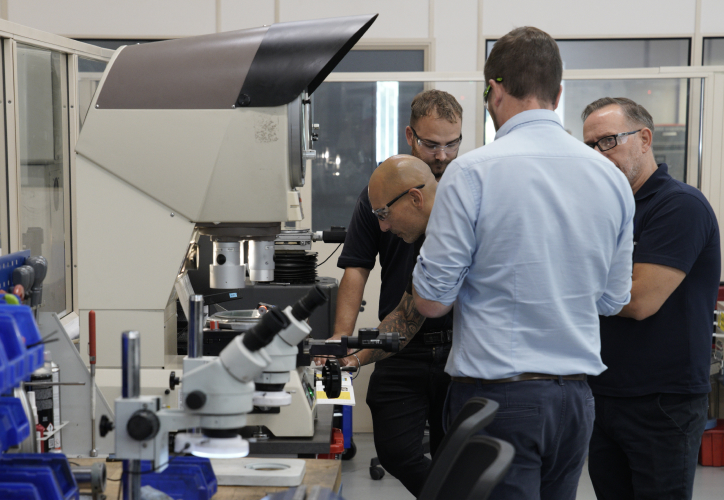

- Collaborate with production partners to refine tolerances based on actual manufacturing capabilities.

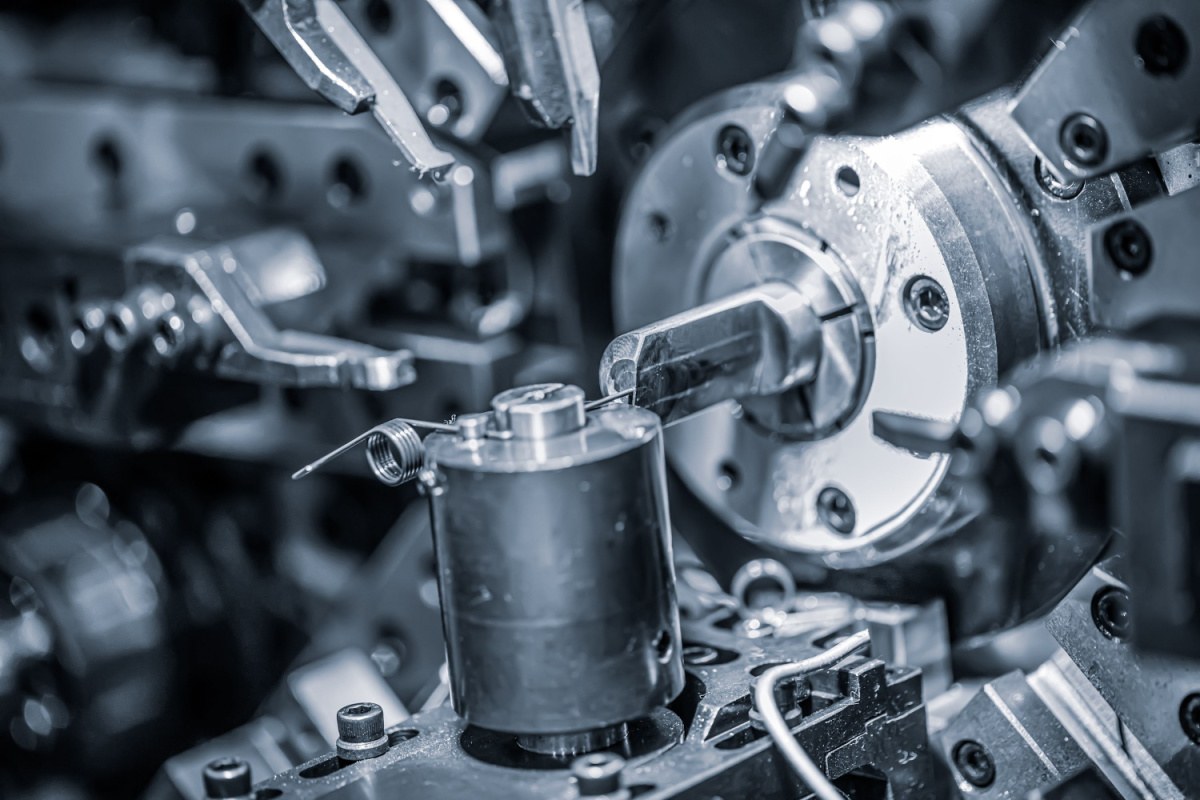

Invest in scalable machinery and automation

Machinery used for prototyping is often ill-suited for volume production. Investing in or partnering with providers who operate high-precision, automated equipment is essential for consistent outputs. By adopting certain technologies early in the scale-up process, manufacturers can ensure a seamless transition from prototype to production-ready design.

- Micropressing for ultra-thin components, achieving intricate geometries with micrometre-level tolerances.

- In-line laser deburring, which significantly reduces surface roughness without compromising component strength essential for parts used in drug delivery or respiratory devices.

- Vibratory bowl finishing, capable of processing batches efficiently, reducing manual intervention and improving repeatability.

Prioritise material selection for long-term repeatability

Not all materials behave the same under high-volume manufacturing conditions. Materials that are perfect for a handful of prototypes may degrade tooling or lead to deformation in continuous cycles.

You need to know which material suits your design, whether it's 304/302 stainless steel for strength and corrosion resistance or nitronic for high ductility and stress tolerance in complex geometries.

In light of this, selection should be a dialogue between design engineers and manufacturing partners to optimise for performance and manufacturability at scale.

Eliminate edge roughness and surface irregularities

High surface roughness affects performance and can be a dealbreaker for compliance from harbouring particulates, increasing wear and shortened device lifespan. Precision finishing methods like laser deburring have proven effective in achieving ultra-low surface roughness without damaging thin or delicate components. Integrating such processes into the production line ensures consistent output, reducing the risk of batch rejection.

Build repeatability into the production ecosystem

Repeatability comes from the entire manufacturing ecosystem rather than just a combination of design and materials. Integrating custom and modular tooling like die sets that enable precision with reduced maintenance downtime. Component traceability is another important aspect that helps ensure compliance and identity failure points before it's too late. On top of this, automation brings an additional layer that reduces variability and enhances throughput. The goal is to engineer a scalable process that delivers identical outcomes with every cycle.

Confidently scale with Advanex Medical as your partner

Bringing a medical device from prototype to scalable production demands a deep understanding of manufacturability, precise tolerance control, smart material selection and investment in scalable, high-quality processes. This is where Advanex Medical excels.

As a global leader in medical component manufacturing, Advanex Medical provides the technologies and expertise needed to transform complex prototypes into compliant, repeatable and high-volume production lines. Our end-to-end support spans concept development all the way to full-scale manufacturing. All of which is delivered from dedicated, medical-grade facilities designed to meet the most rigorous industry standards.

If you're ready to scale confidently, reduce scrap rates and accelerate time-to-market without compromising on quality, Advanex Medical is your trusted partner. Download our guide below to find out more about our DfPM principles or contact a member of our team today.