The UK government’s recent announcement to introduce weight-loss jabs for unemployed individuals with obesity marks a pivotal step in addressing public health concerns and reducing the strain on the NHS. These jabs, which are expected to become more mainstream, will drive significant demand for auto-injector devices that allow patients to self-administer their medication. This surge in demand has widespread implications for pharmaceutical companies, medical device design houses, and manufacturers alike, as they navigate the challenges of producing these devices on a much larger scale.

The Challenges Ahead

The expected rise in demand for single-use auto-injector pens presents both opportunities and challenges for pharmaceutical companies, medical device design houses, and manufacturers. As the rollout of these treatments expands, the entire supply chain will need to collaborate effectively to meet new demands.

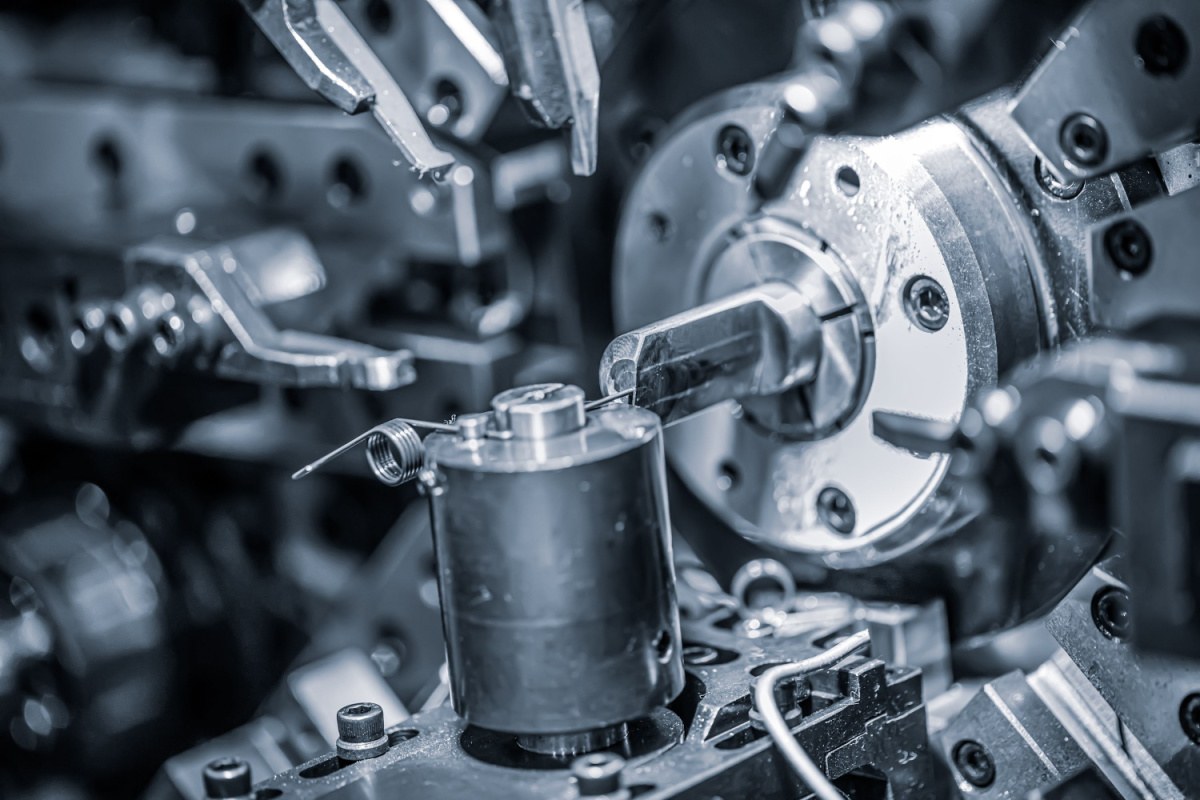

1. Production Scale-Up: Manufacturers will face the challenge of rapidly increasing production capacities. Expanding facilities and leveraging advanced automation will be critical to ensure the output can meet both the scale and precision required. For design houses, optimising designs for manufacturability will play a key role in making production efficient and cost-effective.

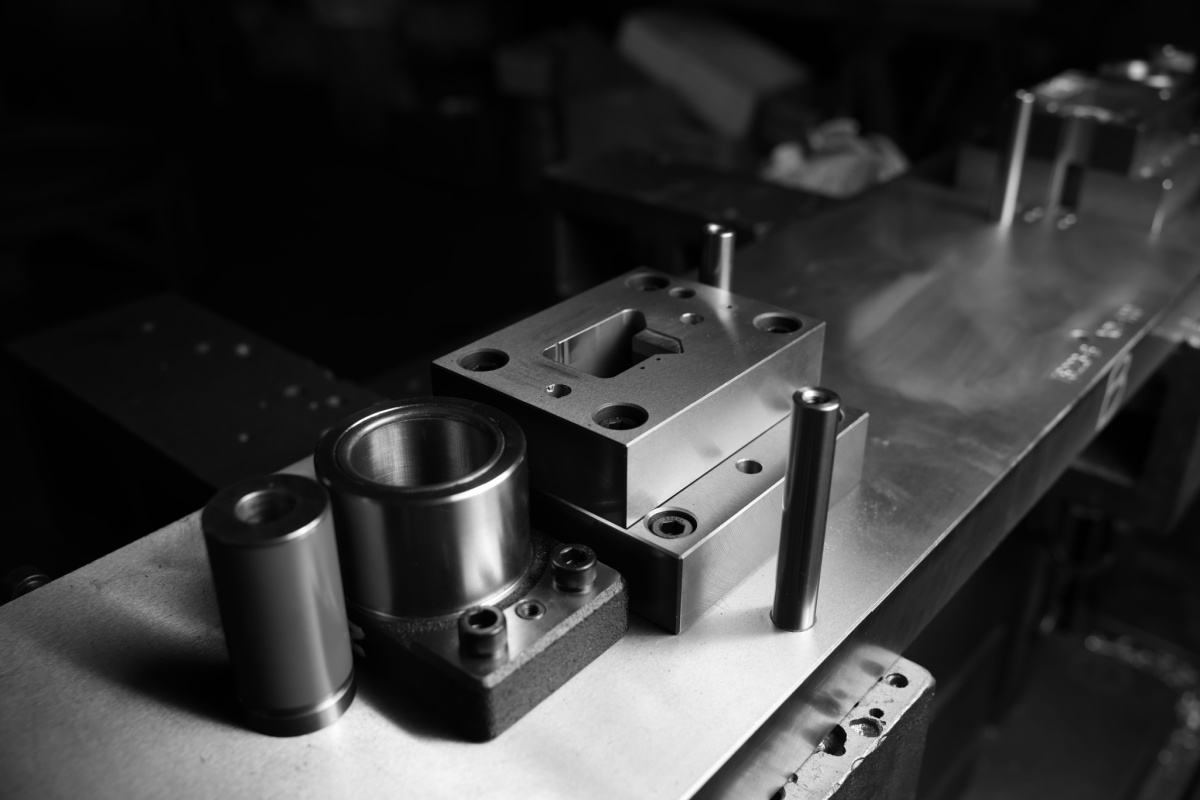

2. Component Shortages: Key components like compression springs, essential for the operation of auto-injectors, may experience shortages as demand surges. These springs need to meet strict standards for durability, corrosion resistance, and performance. Ensuring reliable, scalable sourcing will be critical to keeping production lines moving.

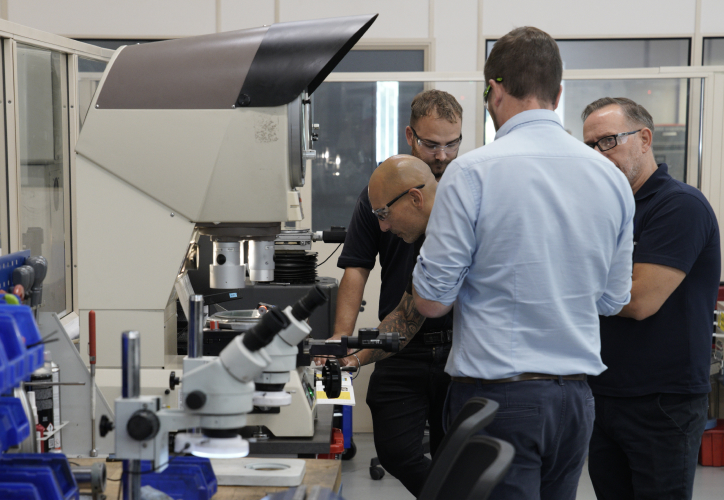

3. Maintaining Quality: High-volume production can sometimes lead to quality variations, but in the medical device industry, consistency is paramount. Manufacturers must have stringent quality control processes in place to ensure that each batch of products meets regulatory standards. Design houses, too, must ensure their designs are easily scalable without sacrificing quality or reliability.

4. Supply Chain Resilience: The strain on global supply chains could make sourcing essential materials like high-grade plastics and metals more difficult. Pharmaceutical companies and manufacturers need to work with partners that have robust, diversified supply chains to avoid bottlenecks and ensure continuous production.

Overcoming the Challenges in Auto-Injector Production

Investing in advanced automation technology is key to ensuring efficient production. Automating assembly processes can help manufacturers handle the larger volumes required while maintaining precision and reducing costs. Along with this, diversifying supply chains will help reduce the risk, this includes securing multiple suppliers for critical parts like compression springs, ensuring stable and uninterrupted production.

Design for Manufacturability (DfM)

To overcome production challenges, it's likely that design changes will need to be made to ensure devices are better suited for large-scale manufacturing. This is where Design for Manufacturability (DfM) becomes crucial. By integrating DfM principles early in the design process, pharmaceutical companies and their manufacturing partners can optimise auto-injector designs to simplify assembly, minimise material use, and enhance production efficiency. This collaboration between design teams and manufacturers helps streamline processes, reduce complexity, and ensure that devices can be produced consistently and at high volumes without compromising quality.

Future Outlook: What's coming next?

Spring Design

As the UK weight-loss jab programme moves forward, the demand for self-administered drug delivery systems like auto-injectors is set to grow. Components like compression springs, which are essential to the functionality of these devices, will require innovative approaches to ensure they meet both the precision and scalability demands of high-volume production.

Spring relaxation becomes an increasingly important factor to address. This occurs when springs lose tension over time, potentially affecting the injector’s ability to deliver the correct dosage. Given that these devices may be purchased but not used immediately, potentially sitting on shelves for extended periods once sold, maintaining spring tension is crucial to ensuring the injector functions properly when eventually used.

Private Medical Care

The UK’s weight-loss jab programme is just one part of a much larger global trend. As self-administered drug delivery systems like auto-injectors become more common, the demand for these devices is expected to surge. Beyond public healthcare initiatives, many individuals are now turning to private healthcare providers or paying out-of-pocket for access to these treatments. As a result, the demand for auto-injectors in the private market alone is set to grow significantly.

As both public and private sectors increase their use of these devices, pharmaceutical companies, design houses, and manufacturers will need to stay ahead of the curve. Those who can innovate and adapt their production processes to meet this growing demand will be well-positioned for long-term success.