Medical devices continue to shrink in physical size. And now, with the advent of many advanced, smart communications technologies, they are increasingly complex – with more features than ever before. For functional components like wire forms and shapes, this can have ramifications on their performance and longevity.

In drug delivery devices, reliable performance and patient usability are paramount. In a smaller, more compact device, this has ramifications on components such as wire forms, where their physical form can determine their longevity, force loads and performance. In pharmaceutical contexts, where patient outcomes trump all other requirements, this necessitates the support of wire shaping and forming experts. Preferably, experts that can work to industry-beating tolerances and support design engineers in developing products that are not only innovative, but reliable.

The importance of tight manufacturing tolerances

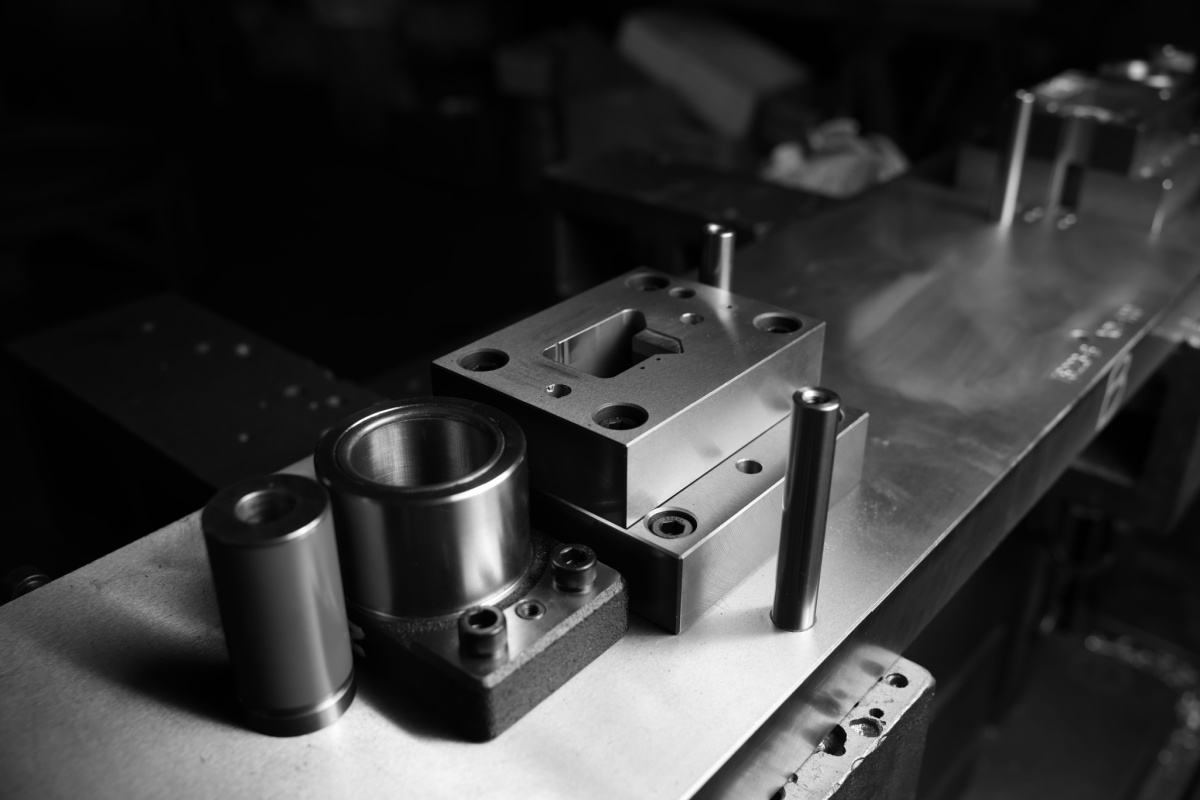

Manufacturing tolerances in medical wire forms refer to the allowable variation in a wire form's dimensions and properties compared to its intended design specifications. These tolerances encompass various aspects of the final product, including:

- Dimensional tolerances: This refers to the acceptable deviations in size, such as diameter, length, bend angles and loop dimensions. Tighter tolerances ensure precise control over the final shape of the wire form.

- Material properties: Tolerances can also apply to the material properties of the wire itself, such as tensile strength, surface finish and spring rate. Consistent material properties are crucial for ensuring the wire form performs as intended under stress and repeated use.

- Geometric tolerances: This refers to the acceptable variations in a wire form's shape beyond simple dimensions. This can include factors like roundness, bends and surface profile. Tight tolerances in these areas ensure smooth movement, proper engagement with other components and minimise friction.

Reasons for the tighter required tolerances for medical wire forms

Miniaturisation and patient comfort

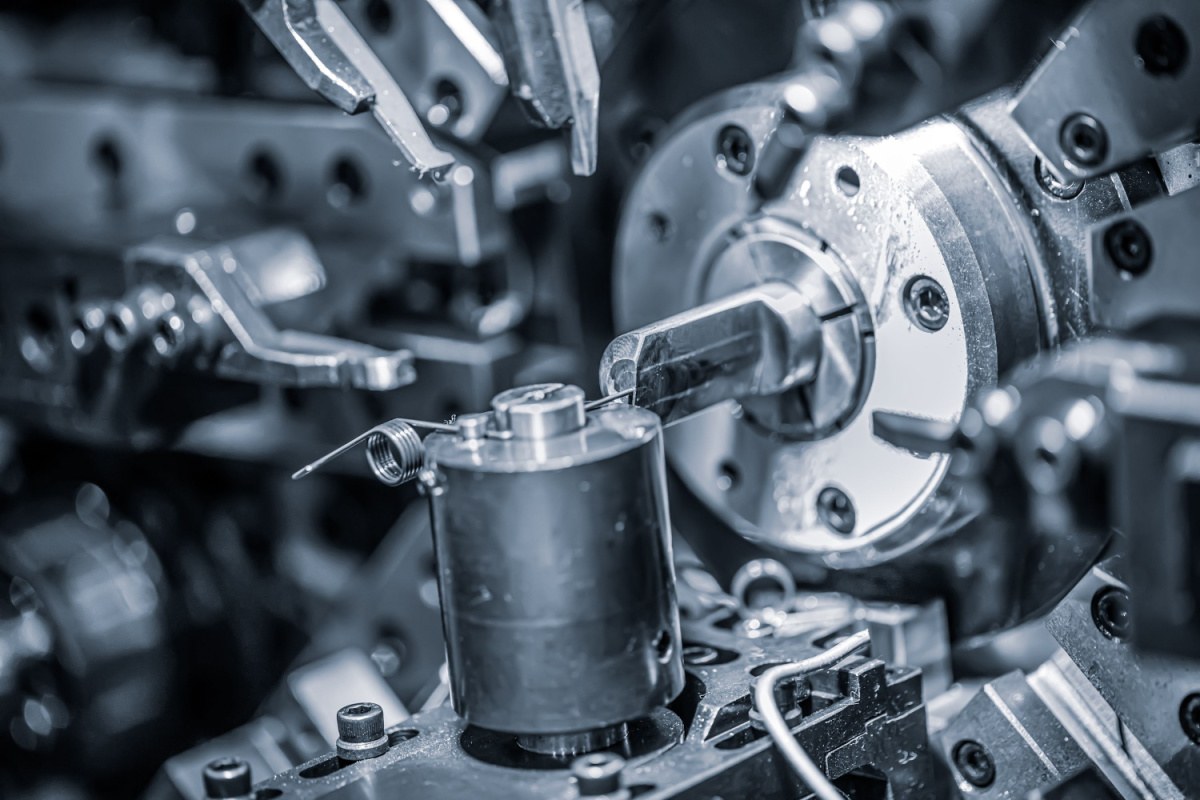

There is a growing trend towards miniaturisation in medical technology. This is because smaller medical devices bring convenience and comfort for patients and users. Devices like inhalers and epipens have to be transported by patient, highlighting the value in making them smaller and more portable. This miniaturisation places an inevitable strain on wire form tolerances to perform their desired function in confined spaces.

Features and shelf life

As medical innovation progresses, so does the complexity of medical devices. Devices like blood glucose samplers need to perform multiple functions and have higher tolerances as a result. Tighter tolerances through precision machining ensure components like springs and wire forms perform their functions with high reliability. For instance, inhalers and insulin pumps rely on precise mechanisms to deliver critical doses of medication accurately. Any deviation from specified tolerances can lead to device failure, potentially resulting in under-dosing or overdosing, which can have serious health implications.

Compliance and contaminants

The medical device industry is one of the most heavily regulated. Regulatory bodies such as the FDA, EMA and MHRA enforce rigorous standards to ensure devices are safe and effective. Tighter tolerances help manufacturers meet these strict specifications, particularly in terms of device cleanliness and integrity which are critical to passing regulatory audits and achieving market approval. In the case of particulates, tight tolerances can help reduce the surface roughness of wire forms that can harbour bacteria and other contaminants, thus minimising the risks associated with particulate matter.

The need for a medical manufacturing partner has never been greater

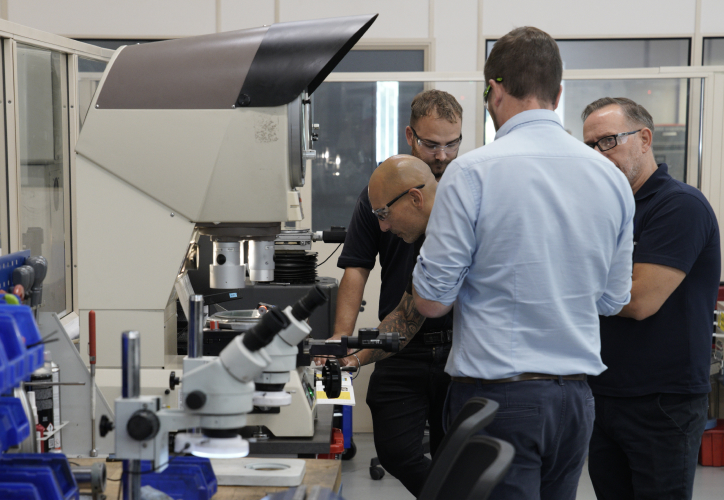

In light of the increasing manufacturing tolerances of medical wire forms, the importance of having a dependable manufacturing partner cannot be overstressed. This partnership is crucial for maintaining the stringent tolerances required in medical wire forms so that devices can successfully navigate the complex landscape of regulatory compliance and market demands.A trusted partner brings expertise in precision engineering and manufacturing processes that are essential for the production of high-quality medical wire forms and devices. As a result, manufacturing repeatability can be enhanced, scrap rates can be reduced and innovative solutions can be implemented to improve overall productivity.

Partner with the industry experts at Advanex Medical

As the landscape of medical device manufacturing evolves, partnering with an experienced and reliable manufacturer becomes imperative. Only one with a global presence, high-grade facilities and deep industry knowledge can accommodate the tight tolerances of medical devices whilst enhancing productivity; this is what separates Advanex Medical from the rest.

Advanex Medical is a leader in the medical industry, with the ability to enhance the precision, compliance and reliability of your medical device manufacturing. Connect with our experts who are ready to help you navigate the complexities of medical device production and ensure your products meet the highest standards of quality and efficiency.

.jpg?width=352&name=shutterstock_1051333151%20(1).jpg)