Particulate contamination poses a significant challenge for medical manufacturing, particularly for wire forms used in drug delivery systems, inhalers, surgical instruments and many other devices.

Wire forms, though small in size, have a disproportionate impact on device safety and reliability. If not properly engineered, they can shed particulates during manufacturing, sterilisation or use, and as such can easily lead to a failure in passing medical trials.

To avoid this risk, medical device engineers need an understanding of how material selection, design strategies and post-processing techniques can be leveraged to minimise particulate contamination from wire forms in medical devices.

Why material selection is an important first-step in minimising particulates

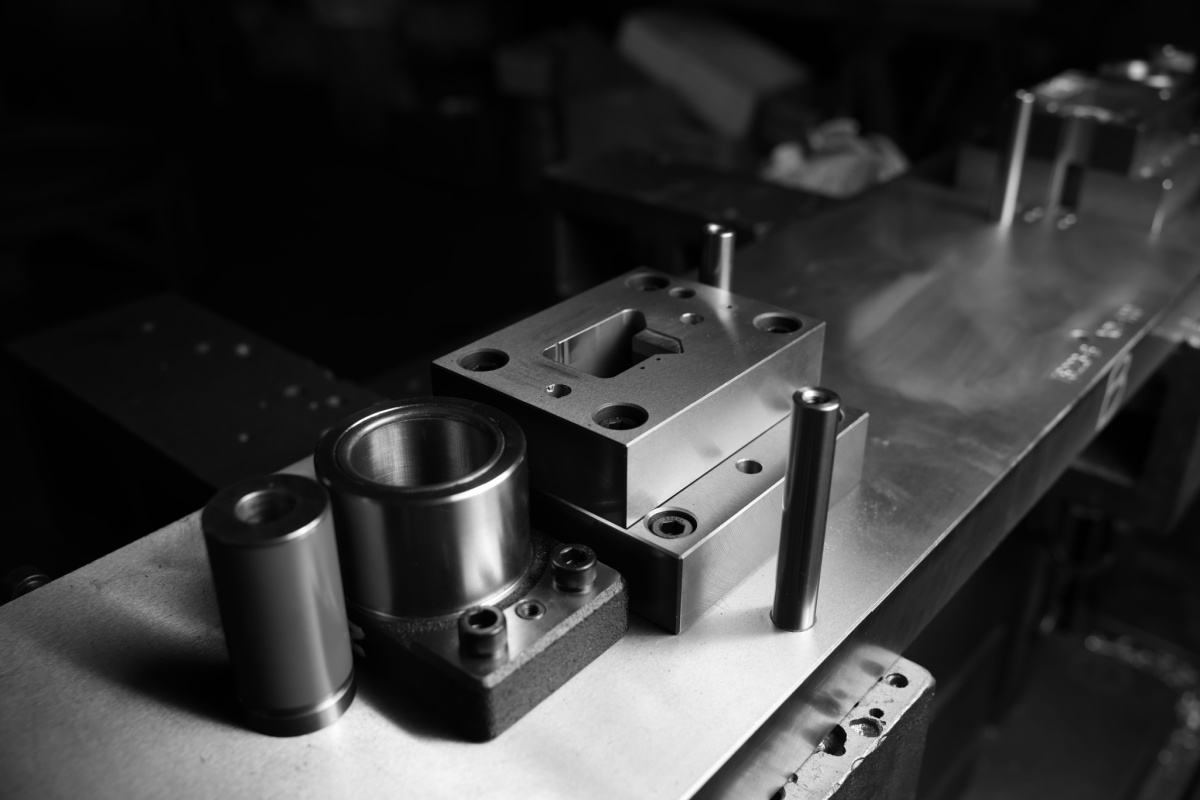

Choosing the right material is the first crucial step in reducing particulate risk. Wire forms are subject to high levels of mechanical stress like bending and compressing across multiple axes. If the material lacks the right amount of ductility then microfractures, flaking and surface degradation can take place, which all increase the likelihood of particulates. By selecting materials with right surface stability and mechanical properties, manufacturers can directly reduce the risk of contamination.

- Nitronic stainless steel offers superior ductility and high resistance to fatigue and stress, making it ideal for complex wire forms. Its smooth, stable surface helps prevent particulate generation during forming.

- Phosphor bronze provides excellent corrosion resistance and a naturally smoother surface profile. This material is particularly useful in high-humidity or long-shelf-life devices.

- 304 and 302 stainless steels are commonly used due to their availability and balanced performance. However, their mechanical properties need to be carefully matched with appropriate post-processing to avoid surface breakage or flaking during forming.

Tackling particulates through post-processing

Even the best choice of wire form material can produce unwanted particulates if post-processing is not performed properly. Surface finishing, deburring and cleaning techniques play a critical role in ensuring wire forms avoid introducing contaminants into the device environment.

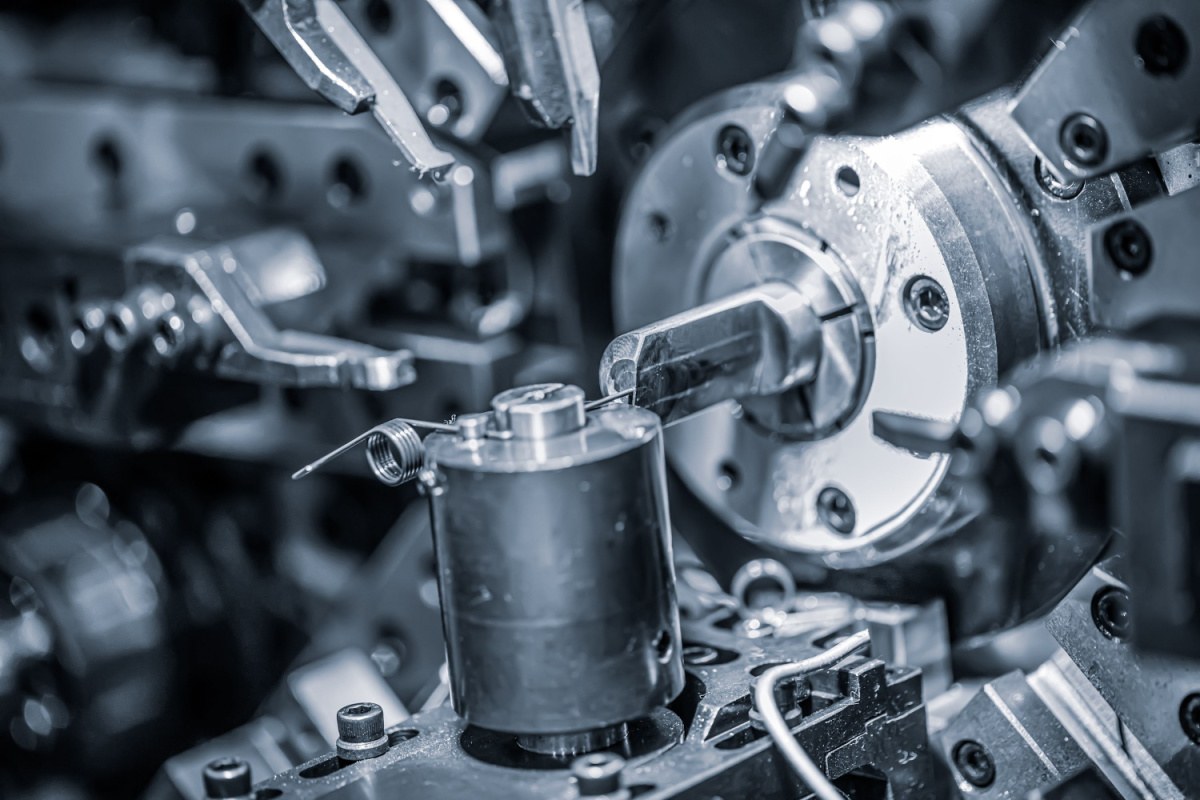

Laser deburring

One of the most advanced methods for eliminating burrs (a common source of particulates) is laser deburring. Traditional mechanical deburring techniques can deform ultra-fine wire forms or introduce new particulate risks. Laser-based solutions remove burrs cleanly and precisely, shaping the end of the wire into a smooth dome without damaging the surrounding geometry.

For example, integrating laser deburring on drug dose counter components reduced particulate presence to undetectable levels, ultimately cutting rejection rates from 40% to virtually 0%.

Additional surface finishing techniques

Passivation can be used to remove surface contaminants and enhances corrosion resistance, particularly important for stainless steel wire forms. This chemical process creates a passive oxide layer that minimises surface degradation under repeated sterilisation.

Electroplating, such as nickel or silver coatings, adds a uniform protective layer that reduces friction and limits particulate shedding during use.

Oiling can be used as a temporary measure during manufacturing to reduce wear. However, this must be carefully removed prior to assembly to meet biocompatibility standards.

Precision cleaning

Wire forms need to be thoroughly cleaned using validated, medical-grade wash systems. Ultrasonic cleaning, in particular, can remove microscopic particles that conventional washing might miss. On top of this, cleanroom packaging ensures that no environmental particulates compromise the cleaned component prior to assembly to minimise rejection rates.

Designing medical devices with wire form particulate in mind

Designing wire forms with particulate reduction in mind is just as important as material and post-processing selection. Factors such as bend radius, coil tightness and geometry complexity influence how prone a form is to surface stress and microcracking. In light of this, there are key design strategies to incorporate early in the design cycle to help avoid costly redesigns and ensure components pass compliance testing with minimal rework.

- Avoid tight internal radii that push the material past its elastic limit.

- Limit complex overlapping features that are hard to clean or deburr.

- Incorporate standard tolerances that align with repeatable manufacturing processes, reducing the risk of burrs or surface fatigue during forming.

Partner with a leading expert for medical manufacturing success

Particulate contamination from wire forms is a major cause of rejection in medical device manufacturing, particularly in drug delivery systems where regulatory scrutiny is high. Getting each element of manufacturing right is essential to ensure device cleanliness and compliance from the outset.

Advanex Medical specialises in producing ultra-clean, precision-formed wire components for the most demanding medical applications. We help manufacturers reduce rejection rates and achieve batch-to-batch consistency across high volumes with dedicated medical-grade facilities, in-house expertise and advanced deburring and finishing technologies (including laser deburring for ultra-thin components).

To dive deeper into optimising wire forms for compliance, cleanliness and production efficiency, download our guide below.

.jpg?width=352&name=shutterstock_1051333151%20(1).jpg)