Devices that interact with human bodies, deliver drugs or assist in surgery are subject to some of the most stringent regulatory oversight across any industry. And for good reason, as patient safety and clinical efficacy depend on it.

For manufacturers, the cost of non-compliance can be catastrophic. Product recalls, high rejection rates, lost revenue and, more gravely, damage to reputation. That’s why "compliance-by-design" should be baked into every stage of the product lifecycle. From concept and material selection through to manufacturing processes, packaging and post-market surveillance.

Medical regulatory landscape - no room for error

Medical devices in the UK and EU must adhere to the Medical Device Regulation (MDR), a complex and exhaustive framework designed to ensure devices are safe, effective and fit for purpose. This includes robust clinical evaluation, risk management protocols and rigorous quality management systems (such as ISO 13485). In the United States, the FDA’s 21 CFR Part 820 outlines similar expectations under the Quality System Regulation (QSR).

Passing clinical trials and gaining certification is a difficult multi-year process. Minor oversights in documentation or process control can very easily derail entire product launches. Within this testing window, devices need to prove long-term reliability and safety within real-world operating conditions. In this regulatory climate, reactive compliance is not a viable approach. Proactive, evidence-driven compliance needs to start from the design phase and continue throughout the supply chain.

What is compliance-by-design?

Compliance-by-design is the practice of embedding regulatory requirements and best practices into every stage of product development and manufacturing. It revolves around designing processes, specifications and documentation that make compliance intuitive, auditable and repeatable.

This approach typically includes:

- Designing for manufacturability and regulatory testing

- Material selection with compliance in mind

- Documenting decisions and design changes as a clear audit trail

- Integrating inspection and verification into production

- Ensuring traceability of components, processes, and packaging

- Planning for validation and sterilisation from the outset

Compliance-by-design reduces the risk of late-stage failures and facilitates a smoother path to market. It also enables consistent quality and minimal scrap, which are essential in high-volume, high-precision production environments.

Embedding compliance into specifications, packaging, and processing

Compliance depends on every detail of the manufacturing process aligning with regulatory expectations from the outset. Manufacturers can proactively prevent failures and ensure consistent product quality by embedding compliance into specifications, packaging and processing.

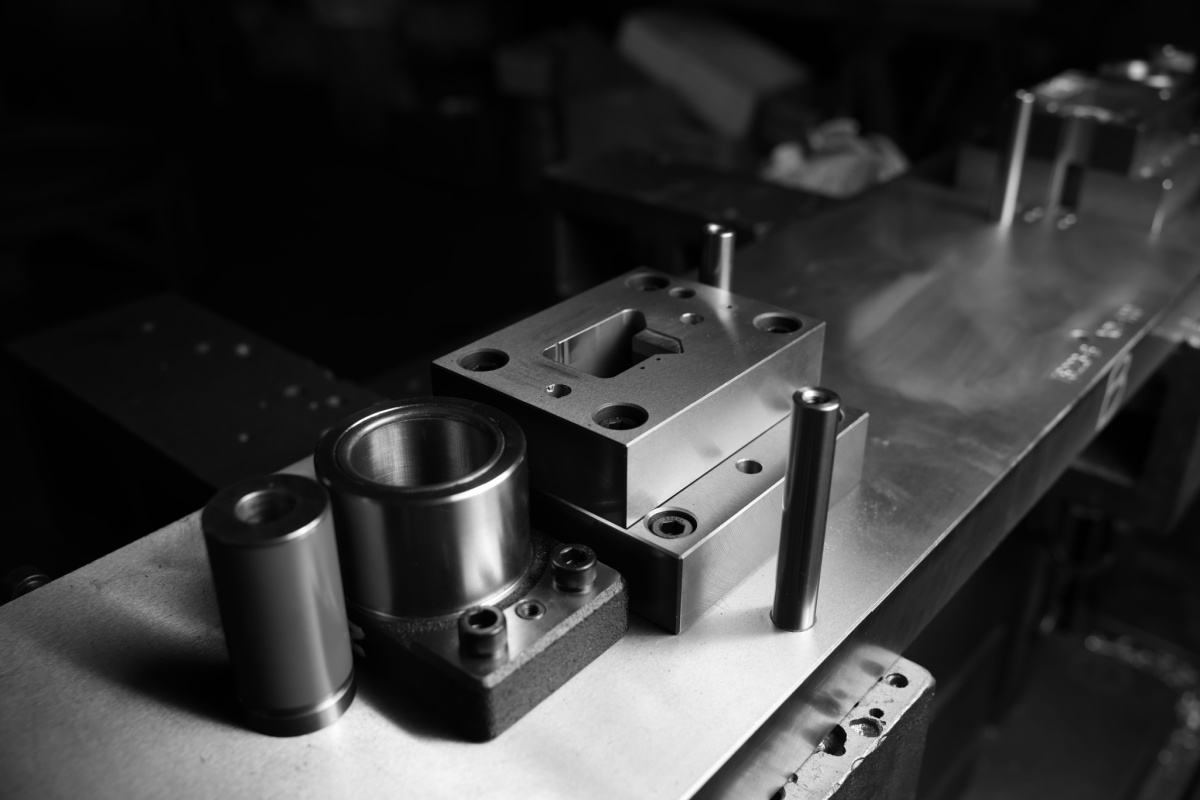

Design and specifications

Designing with compliance in mind means working backwards from the required clinical performance and regulatory expectations. This includes controlling edge roughness, managing particulates and planning for sterilisation and cleanliness from the start.

For example, wire forms and thin metal pressings need to be designed for biocompatibility and repeatability as much as mechanical performance. Even minor deformities or surface roughness can cause devices to fail clinical trials due to contamination or mechanical degradation.

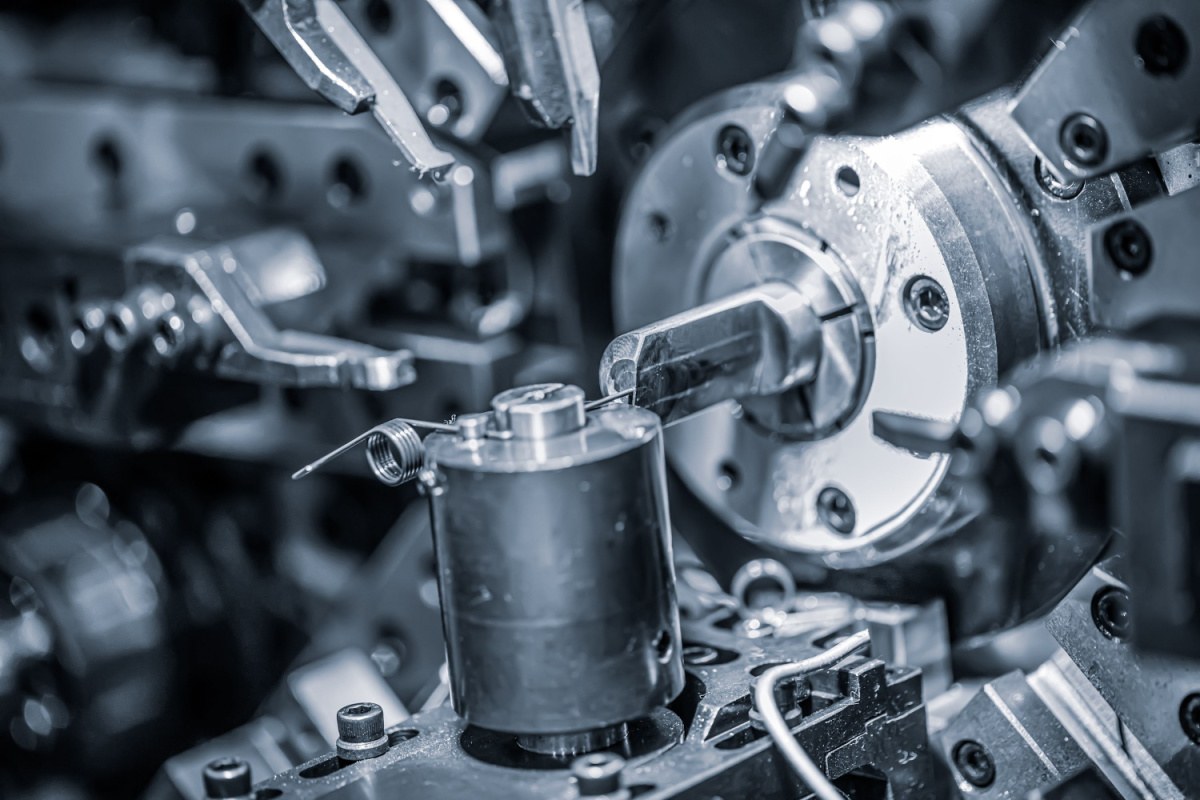

Surface finishing and deburring

Deburring and surface finishing are compliance-critical as rough surfaces can harbour bacteria, attract particulates and make cleaning difficult, violating MDR hygiene requirements.

Advanced methods like in-line laser deburring have proven highly effective in minimising surface particulates. By reducing edge roughness and eliminating debris at source, rejection rates can be brought down from high levels to virtually zero.

Packaging and handling

Ultra-thin, high-precision components are particularly susceptible to deformation during transit or assembly. Poor packaging can compromise sterility or structural integrity. That’s why packaging must be part of the design brief rather than an afterthought. Tailored solutions like reels or trays can protect parts and support automated assembly that ensures cleanliness.

Why documentation is your best defence

Regulatory audits under MDR demand a clear, end-to-end paper trail. Every decision from material sourcing to finishing methods must be traceable. This is where compliance-by-design proves invaluable. Without this integrated approach, audits become a scramble. With it, they become a formality.

By embedding documentation checkpoints throughout the development process, manufacturers ensure that:

- Each component is linked to a validated specification

- Every batch can be traced to source materials and processes

- Deviations are documented and justified

- Test data is connected to design files

- Final packaging, labelling and IFUs (Instructions for Use) are version-controlled and compliant

Utilising compliance as a competitive advantage

In the current regulatory environment, compliance is non-negotiable but not a barrier. When considered early, designed carefully and documented thoroughly, compliance can become a competitive advantage.

Manufacturers who adopt a compliance-by-design approach de-risk their development pipelines to directly accelerate time to market and build trust with regulators and healthcare providers.

At Advanex Medical, we specialise in helping manufacturers bake compliance into their DNA from processes like ultra-thin pressings and complex wire forms to robust deburring (all traceable processes). With precision tooling, regulatory expertise and medical-grade facilities, we support you in building devices that meet global compliance standards.

Download our guide below to find out more about our design for pharmaceutical manufacturing approach and how it simplifies compliance.