Selecting the appropriate material for deep drawn medical components is a crucial step in the manufacturing process. This is because it impacts the formability of the pressing process and ensures that the final components meet the stringent requirements of the medical industry.

This article explores the importance of material selection in deep drawn components, delves into the specific benefits of different metals and highlights how they enhance the performance of medical devices.

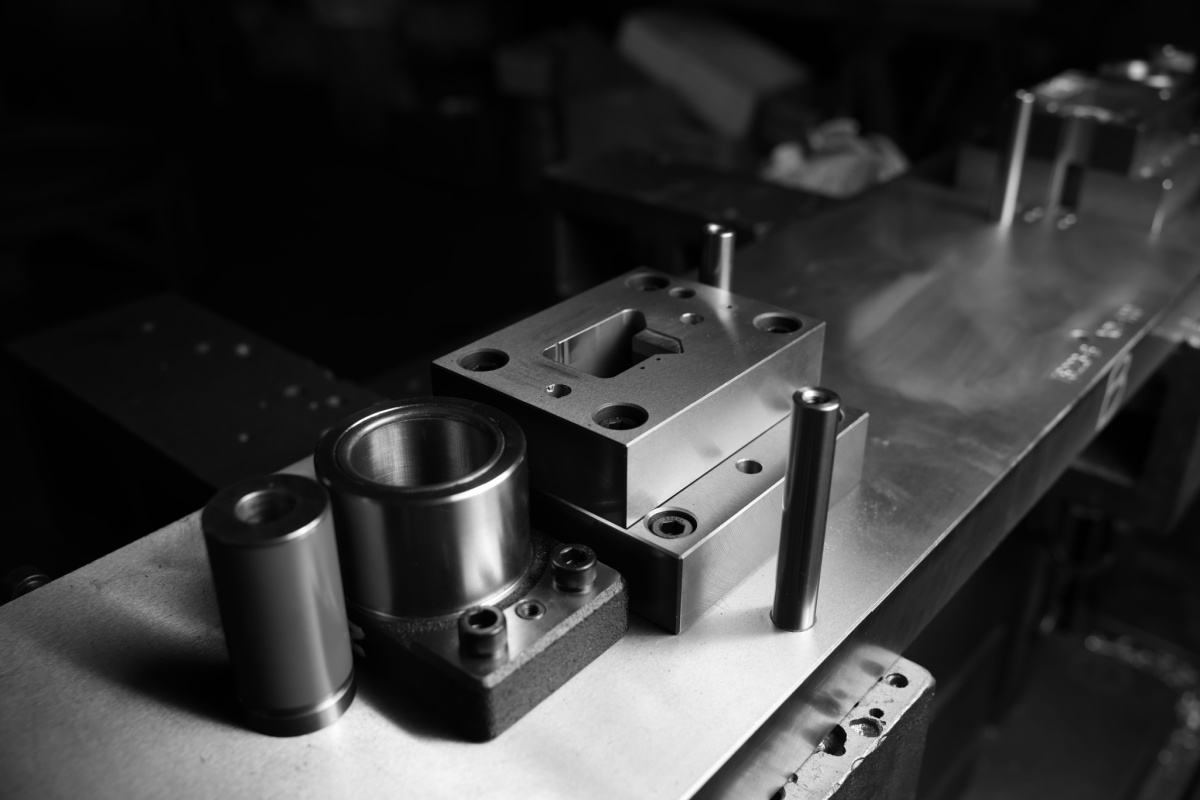

The importance of material selection for deep drawn components

In the deep drawing process, selecting the right material is critical to achieving an optimal Limiting Drawing Ratio (LDR), which determines the extent to which a material can be stretched without permanent deformation. Different materials exhibit varying degrees of formability, ductility and strength, impacting the overall efficiency and success of the deep drawing process. Materials with high ductility can be drawn into more complex shapes and thinner walls, maintaining a high LDR, which enhances the production of intricate and detailed medical components.

The chosen material also affects the manufacturing process itself, reducing the likelihood of defects such as wrinkling, tearing or excessive thinning. Selecting the appropriate material ensures a smoother, more reliable deep drawing operation. Additionally, the material provides unique features and surface characteristics that benefit specific medical components and devices. All in all, material choice is a crucial step in the deep drawing process.Material choices for medical deep drawing

Aluminium

Aluminium is widely used in medical device manufacturing due to its excellent strength-to-weight ratio and corrosion resistance. It is lightweight yet strong, making it suitable for components that need to be durable and easy to handle. Aluminium is also biocompatible, which is essential for medical applications.

Impact on deep drawing process:

Aluminium is favoured for its excellent formability, allowing it to be drawn into complex shapes with high precision. Its low density and high ductility make it easier to achieve optimal Limiting Drawing Ratio (LDR), ensuring the production of intricate and detailed components.

Benefits for medical devices:

- Lightweight: Enhances portability and patient comfort.

- Corrosion resistance: Forms a protective oxide layer, ideal for medical environments.

- Particulate control: Suitable for applications where controlling particulate contamination is critical.

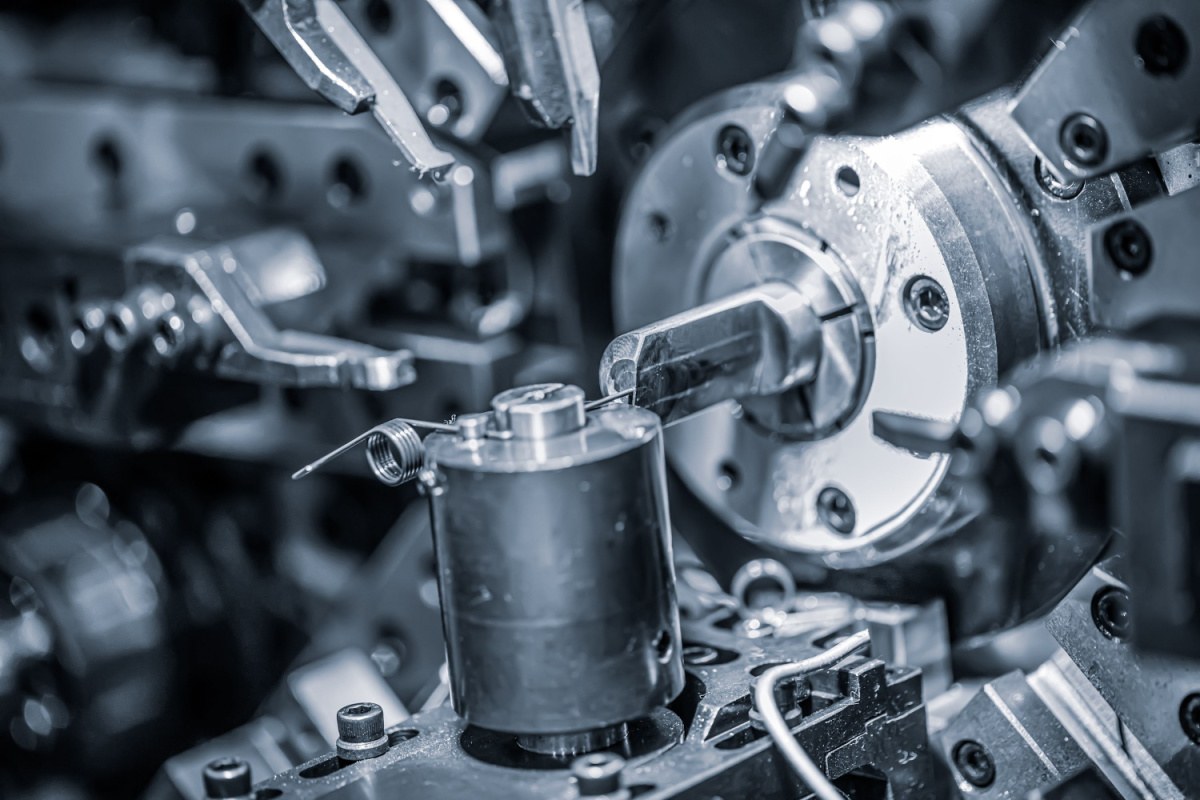

Stainless steel

Stainless steel is a staple in medical manufacturing due to its exceptional strength, corrosion resistance and biocompatibility. It is used for components that must endure significant mechanical stress and exposure to harsh environments, making it ideal for long-term use in medical devices.

Impact on deep drawing process:

Stainless steel is renowned for its strength and resistance to deformation, which are critical for maintaining component integrity during deep drawing. Its high LDR ensures the creation of robust and durable components. That said, making particularly complex or thin components can be unachievable with stainless steel.

Benefits for medical devices:

- High strength and durability: Suitable for components that must endure significant mechanical stress.

- Corrosion resistance: Essential for maintaining integrity in harsh medical environments.

- Particulate control: Ideal for devices that face stringent particulate regulations and need to minimise their presence.

Phosphor bronze

Phosphor bronze, a copper alloy containing tin and phosphorus, is known for its excellent wear resistance, low friction and corrosion resistance. These properties make it suitable for components that require durability and reliability over repeated use in corrosive environments.

Impact on deep drawing process:

Phosphor bronze offers excellent wear resistance and low friction properties, making it suitable for components that undergo repeated motion. Its formability allows for the creation of complex shapes while maintaining a high LDR.

Benefits for medical devices:

- Wear resistance: Ensures longevity and reliability.

- Low friction: Reduces wear and tear on mating surfaces.

- Corrosion resistance: Maintains integrity for devices that face corrosive environments

Get industry leading support to select the perfect material for your medical components

Choosing the right material for deep drawn medical components is crucial for ensuring the performance, durability and safety of medical devices. Each material discussed (aluminium, stainless steel and phosphor bronze) offers unique properties that cater to specific needs within the medical industry. By understanding these materials' features and benefits, you can make informed decisions to optimise the deep drawing process and maintain optimal LDR, ultimately enhancing the quality and reliability of medical components.

Advanex Medical is your ideal partner for navigating the complexities of material selection and deep drawing processes. Our extensive experience and advanced manufacturing capabilities ensure that your medical components meet the highest standards of quality and performance. We can directly support you in choosing the perfect material for your deep drawn components. Contact us today to learn how we can support your next medical device project.