Compact pressed components can be more cost effective and better suited for certain medical devices when compared to metal forming. That said, they often need to provide the best of both worlds when it comes to their features; They need to be reliable and robust for long-term use whilst being extremely thin and lightweight for devices that are getting smaller and smaller.

More often than not, achieving high strength and ultra thin metal pressings is unachievable with standard processes. This emphasises the need for precise and reliable manufacturing solutions, specialised tooling and having design in mind from the get go.

The importance of material selection

Material selection is fundamental to designing high-strength, ultra-thin metal pressings. The most commonly used materials in medical applications include stainless steels and aluminium alloys. These materials offer a balance of strength, durability, and corrosion resistance, which are essential for medical devices that must perform reliably under various conditions.

Stainless steel: Known for its excellent corrosion resistance and strength, stainless steel is ideal for components that must withstand harsh environments and repeated sterilisation processes. However, its toughness can pose challenges during the pressing process, requiring high-quality tooling and precise control.

Aluminium alloys: Aluminium alloys are favoured for their lightweight properties and good strength-to-weight ratio. They are particularly suitable for applications where weight reduction is crucial without compromising structural integrity. However, aluminium's softer nature compared to stainless steel necessitates careful handling to avoid deformation during pressing.

Key design considerations for metal pressings

Beyond material selection, there are several critical factors that must be considered when designing high-strength, ultra-thin metal pressings. This is to ensure the components perform as intended and maintain their integrity throughout their lifespan.

1. Material Tempering

Tempering is a heat treatment process that enhances the material's mechanical properties, such as strength and toughness. For ultra-thin pressings, tempering must be precisely controlled to prevent through-cracking, which can occur due to the thin nature of the material. Proper tempering ensures that the components can withstand the stresses of their application without failure.

2. Surface Finish

Surface finish plays a crucial role in the performance and longevity of medical components. A smooth surface reduces friction, minimises wear, and prevents the accumulation of contaminants. Techniques such as vibratory deburring and laser finishing can be employed to achieve the desired surface quality, enhancing the component's performance and compliance with medical standards.

3. Packaging Solutions

Proper packaging is essential to protect ultra-thin metal pressings during transit and storage. Tailored packaging solutions, such as reels for easy feeding into assembly lines or trays for delicate parts, help maintain the integrity of the components and ensure they are free from damage or contamination.

The Advanex advantage for metal pressing quality

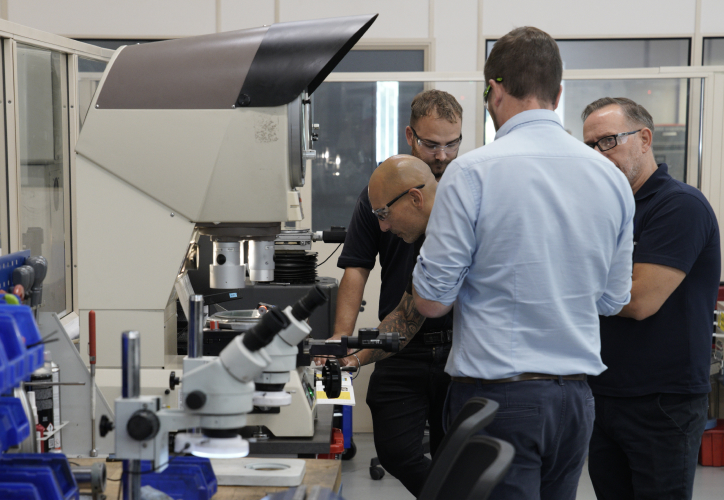

For thorough support in designing high-strength, ultra-thin metal pressings, there is no better manufacturing partner than Advanex Medical. We have decades of experience and have capabilities that include bespoke tooling, advanced quality control systems and comprehensive design support. We understand the unique challenges of medical device manufacturing and offer solutions that enhance product reliability, reduce lead times, and improve overall efficiency.

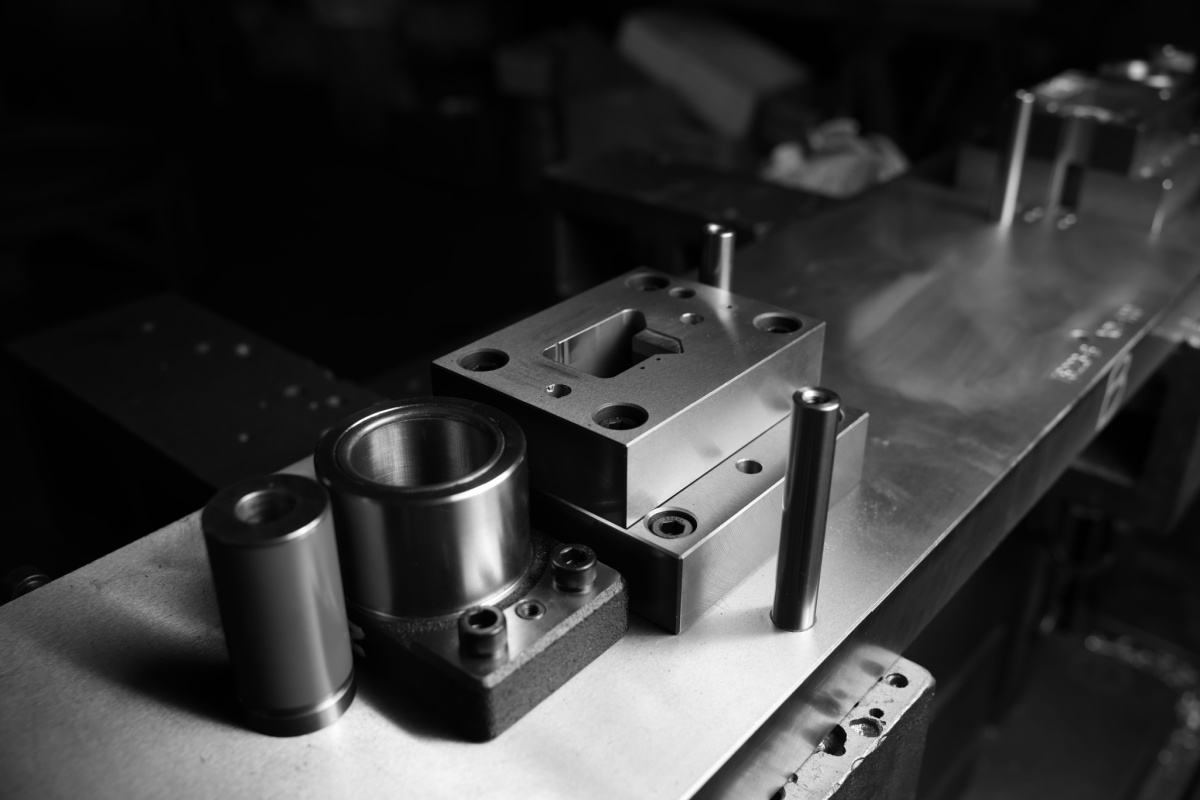

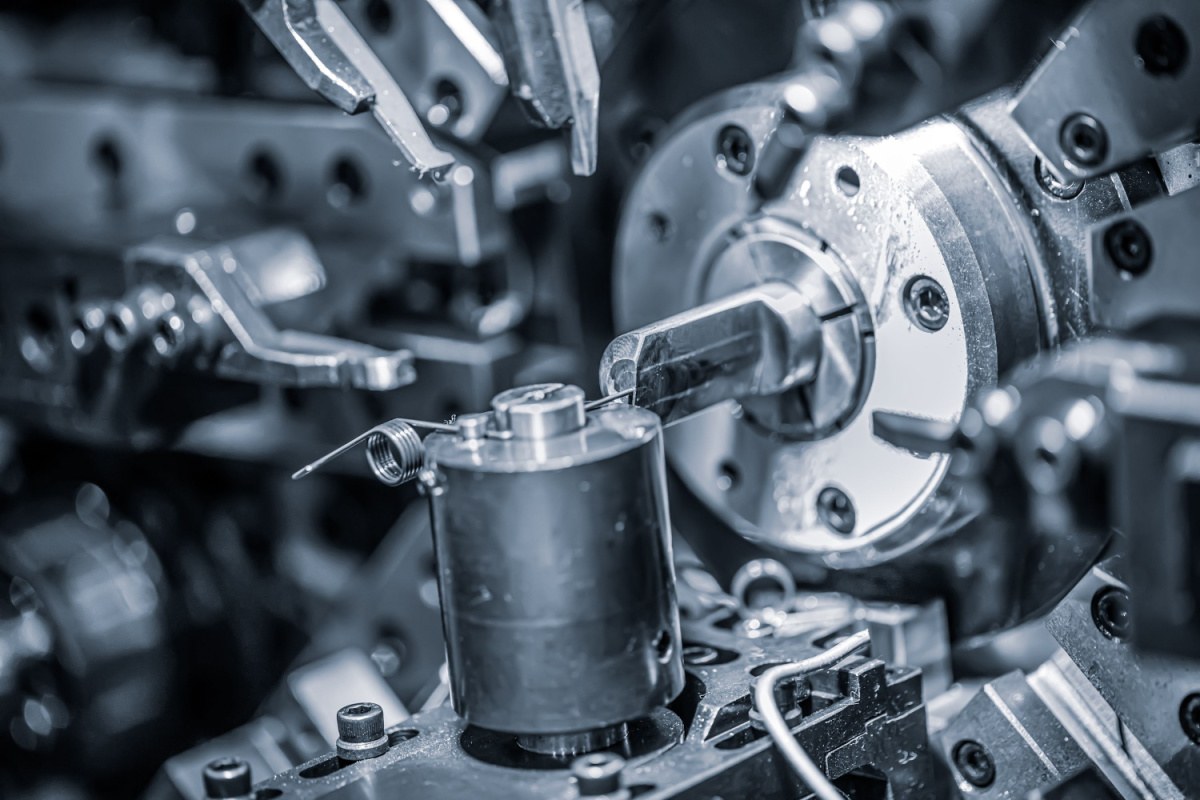

- Precision tooling: Our state-of-the-art tooling technology ensures that each component is manufactured to exact specifications, with tolerances measured in micrometres. We use an advanced technique called micropressing that allows for the creation of highly precise components from ultra-thin materials. Micropressing involves the use of precision tooling to shape materials as thin as a few micrometres, achieving intricate designs with minimal tolerances.

- Comprehensive design support: From initial concept to final production, our team of experts collaborates with clients to optimise designs for manufacturability and performance. We provide valuable insights into material selection, tempering processes, and surface finishing techniques, ensuring that the final product meets all regulatory requirements and performs reliably in its application.

- Global manufacturing presence: With facilities around the world, Advanex offers a global reach with local expertise. Our medical-grade manufacturing environments adhere to the highest standards of cleanliness and quality, ensuring that every component we produce is free from contaminants and ready for immediate use.

Get industry-leading support with Advanex Medical

Designing high-strength, ultra-thin metal pressings for medical applications requires a delicate balance of material selection, advanced manufacturing techniques, and precise quality control.

Advanex Medical's comprehensive approach to design and manufacturing make us the ideal partner for medical device manufacturers. By leveraging our capabilities, you can achieve the highest standards of quality and reliability for your medical components, ensuring they perform flawlessly in the most demanding environments.

To learn more about how Advanex can support your next medical device project, connect with our experts today. We are here to help you navigate the complexities of medical device production and deliver solutions that meet the highest standards of quality and efficiency.