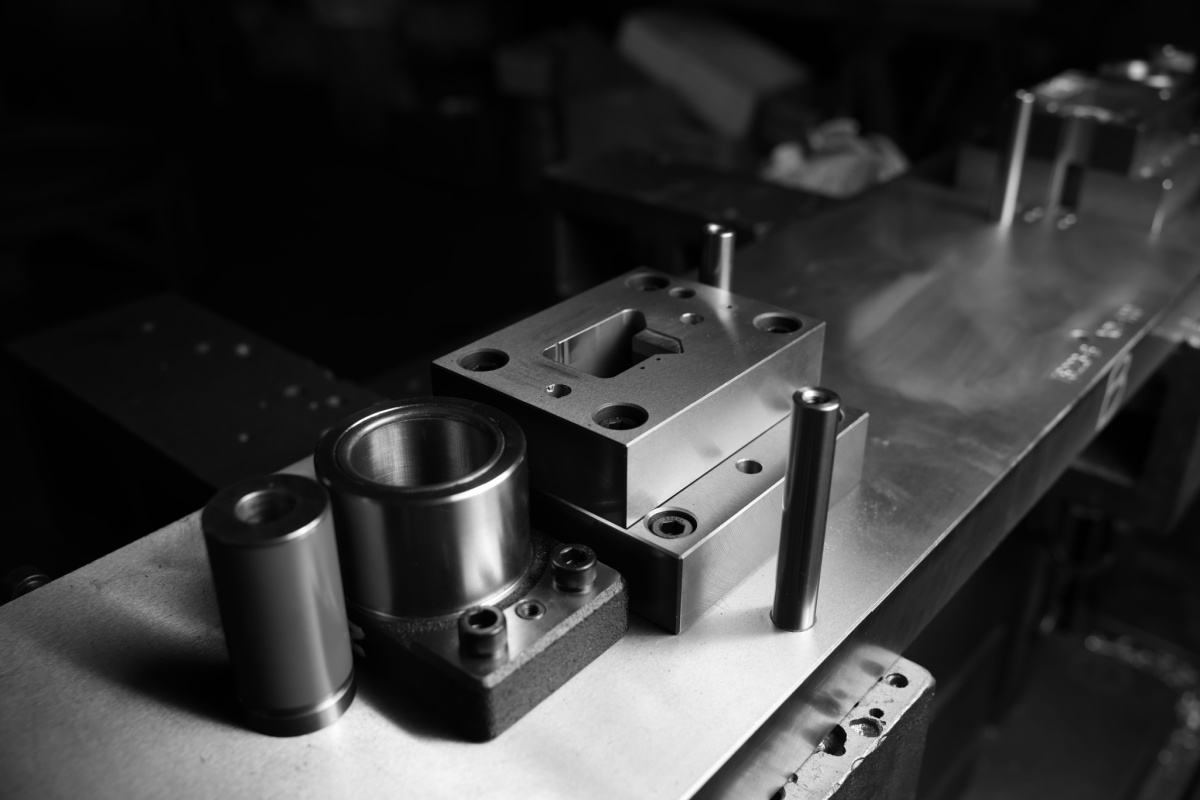

Deep drawn components face particularly tight tolerances as a result of their precise manufacturing process. This leads to the high risk of deformation and permanent damage if handled improperly, highlighting the importance of thorough ejection and handling techniques.

In this article, we will explore the importance of proper ejection and handling of deep-drawn medical components. We will detail how these processes prevent damage and defects, maintain precision and tolerances, and ensure cleanliness whilst enhancing production efficiency.

Why proper ejection and handling of deep-drawn components is crucial

Preventing damage and defects

Maintaining the surface integrity of deep-drawn components is essential for devices to function properly and pass medical trails. Scratches, dents and other damages can compromise these factors and lead to unnecessarily high scrap rates. Proper ejection techniques help avoid these issues by ensuring smooth and gentle removal from the die, which is particularly important for maintaining the clean, smooth surfaces required by regulatory standards.

Maintaining precision and tolerances

Medical components often need to meet very high precision standards. Proper ejection methods are vital for maintaining the tight tolerances specified in the design. This ensures that each component fits and functions as intended in the final assembly. Consistent handling processes also contribute to the repeatability and reliability necessary for high-volume manufacturing, ensuring that each piece meets the same quality standards.

Ensuring cleanliness and sterility

Contamination is a major concern in medical manufacturing. Components must be free of particulates and biological contaminants to ensure patient safety and pass regulatory scrutiny. Proper handling techniques minimise the risk of introducing contaminants, thus maintaining the sterility required for medical devices.

Enhancing production efficiency

Efficient ejection and handling processes are key to minimising machine stoppages and downtime caused by component jams or misfeeds. This keeps production lines running smoothly to meet tight delivery schedules. Additionally, reducing the number of defective or damaged components through proper handling techniques leads to less material waste and associated costs, contributing to overall production efficiency.

What are the actual steps to optimise component ejection and handling?

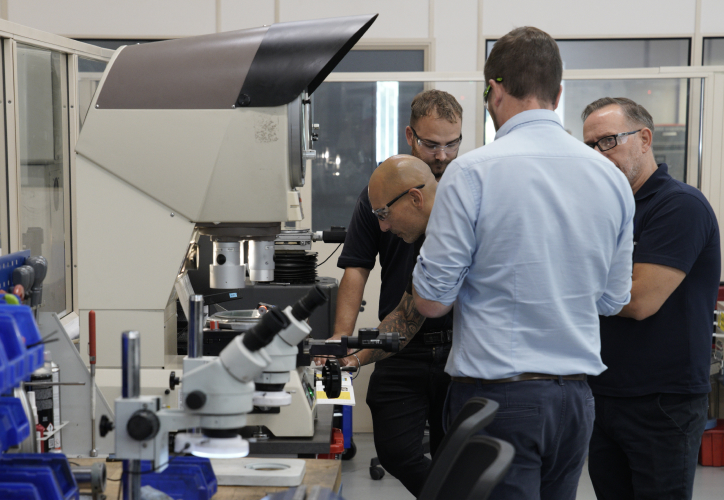

Tooling and equipment

- Precision tooling: High-quality, well-maintained tooling designed specifically for the material and geometry of the component is essential. This ensures smooth and precise ejection without damaging the component.

- Ejection mechanisms: Implementing appropriate ejection mechanisms such as air blasts, mechanical pins or stripper plates can facilitate smooth and damage-free ejection. These mechanisms help in carefully dislodging the component from the die without causing deformation or surface defects.

Surface treatments

- Lubrication: Applying suitable lubricants can reduce friction between the component and the die, aiding in smooth ejection. This is crucial for maintaining the integrity of the component’s surface.

- Surface coatings: Using surface coatings on tools enhances wear resistance and reduces adhesion between the component and the tooling, further ensuring damage-free ejection.

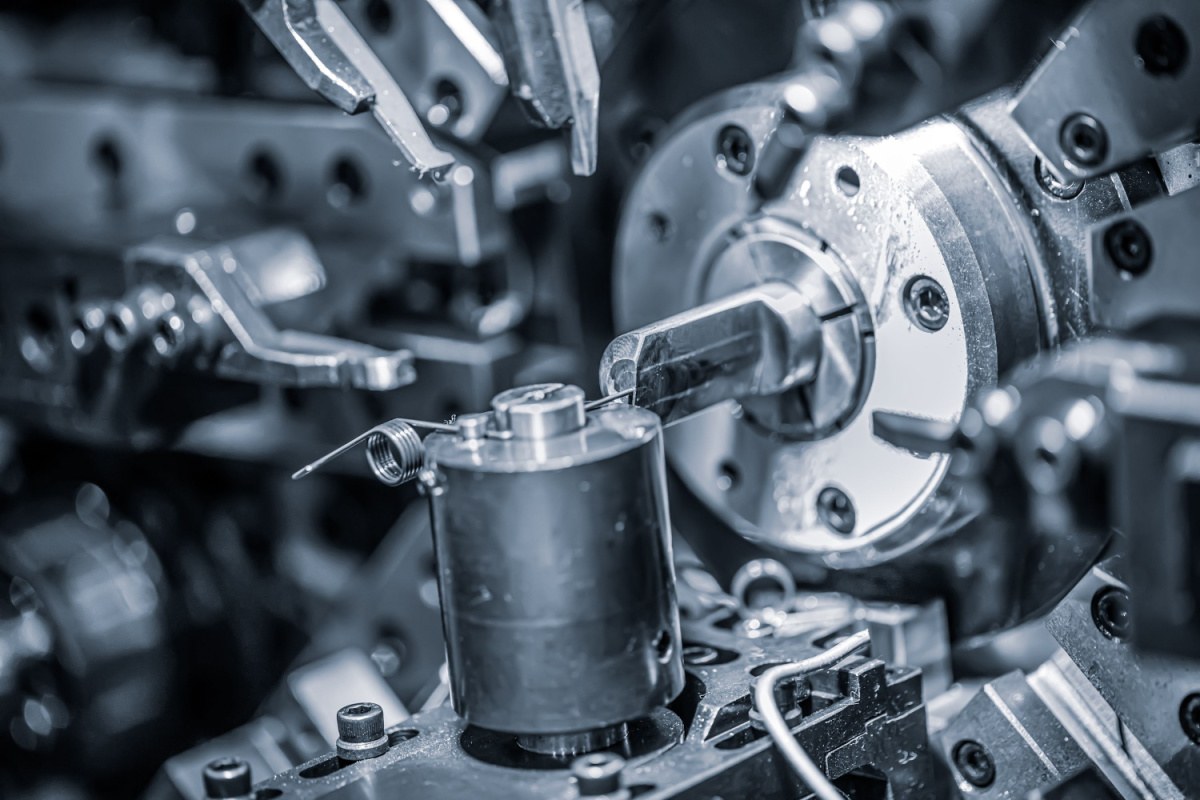

Process parameters

- Controlled ejection force: Adjusting the ejection force to the minimum required to remove the component without causing damage is essential. This helps in preventing warping or other deformations.

- Consistent ejection speed: Maintaining a consistent ejection speed prevents sudden movements that could lead to component damage. Consistency in speed ensures that each component is handled with the same care, preserving its quality.

Handling techniques

- Gentle handling: Utilising soft-touch tools or automated systems to handle components delicately during and after ejection can significantly reduce the risk of damage. These tools are designed to minimise the impact on the component's surface.

- Minimise contact points: Designing handling systems that minimise the number of contact points with the component helps reduce the risk of surface damage. Fewer contact points mean less opportunity for scratches and other surface imperfections.

Partner with the experts in medical component manufacturing

Proper ejection and handling of deep-drawn medical components are vital to maintaining their quality and performance as part of an overall design. By implementing precision tooling, appropriate ejection mechanisms, controlled process parameters and advanced handling techniques, you can ensure the production of high-quality medical components. Automation and robotics further enhance these processes by providing consistent, reliable handling that meets the stringent standards required in the medical industry.

Partnering with an experienced manufacturer like Advanex Medical ensures that these best practices are integrated into your production process, resulting in components that meet the highest standards of quality and reliability. With our expertise in precision engineering and manufacturing, we help you navigate the complexities of medical device production, ensuring your products are ready for market success. Get in touch with our experts today to find out more about how we can support your medical project.